(1) become Eq. 42 0 obj

<>/Filter/FlateDecode/ID[<56DCC911F28ADC8A6CCC9660537B6825><03958CE6B4190B43A54FCBDCDB17A185>]/Index[22 37]/Info 21 0 R/Length 101/Prev 312066/Root 23 0 R/Size 59/Type/XRef/W[1 2 1]>>stream

. Is the fluid corrosive? Ideally, you should choose a pump where the operating point matches the point of maximum efficiency on the pump curve (BEP). Two-phase mixture is pumped until the suction line has been evacuated and the fluid level has been pushed into the front suction intake chamber by atmospheric pressure. P %%EOF

No need to dismantle pipeline system, just lifting off the conjunction flat nut of vertical pump. A centrifugal pump containing two or more impellers is called a multistage centrifugal pump. The suction line is thus continuously evacuated. The pump size of a magnetic drive pumps can go from few watts of power to a giant 1MW. It was important that the pump was capable of lifting the water from the lower to the higher level. Over the lifetime of the pump this can have considerable cost benefits. Dynamic analysis is the evaluation of forces, their frequency input to the pumping system compared to the pump systems natural frequencies and the consequences of their interactions. In self-priming centrifugal pumps with a separation chamber the fluid pumped and the entrained air bubbles are pumped into the separation chamber by the impeller action. They allow you to extrapolate from the specified pump curve and predict how the pump will perform at a different shaft speed or with a smaller (or larger) impeller installed. The energy usage is determined by multiplying the power requirement by the length of time the pump is operating. In normal conditions, common centrifugal pumps are unable to evacuate the air from an inlet line leading to a fluid level whose geodetic altitude is below that of the pump. NPSHA is the total suction head absolute at the suction of the pump, over the vapor pressure of the liquid pumped at its operating conditions. The fluid pressure increases as the fluid is discharged and the bubbles implode. Magnetically coupled pumps, or magnetic drive pumps, vary from the traditional pumping style, as the motor is coupled to the pump by magnetic means rather than by a direct mechanical shaft. Available sizes range from 1-1/4 x 1 to 2 x 1-1/2. More frequently used types of self-priming pumps are side-channel and water-ring pumps. In addition to proper selection, installation and control of the pump are also important for reliability and efficiency. At the right-hand side of the BEP, a pumps throughput is higher than its design specification and there is a danger of cavitation in the impeller. How it operates in practice is determined by the resistance of the system it is installed in: restrictions in the pipework and downstream frictional losses as well as static inlet or outlet pressures. For example, a 350 MW unit would require two feedpumps in parallel. This means that if a pump is operated with an NPSHA equal to its NPSH3, it is cavitating, and performance is reduced by 3 percent due to this cavitation. Select the electric centrifugal pump that suits your operating needs or contact usto learn more about our extensive inventory of pumps and accessories. We are open and serving our customers online and in stores. This is called the static head and, in the conventional sense, is comparable to pumping the fluid to a higher (or lower) reservoir. A centrifugal pump has a best efficiency point (BEP) somewhere on its pump curve. The same effect can be gained by supplying liquid to the pump suction under pressure supplied by another pump placed in the suction line. Figure 4 shows an example of a published curve for a 5 6 11 pump running at 1,770 rpm. If the pump casing becomes filled with vapors or gases, the pump impeller becomes gas-bound and incapable of pumping. NPSHR is a minimum NPSHA given by the manufacturer, which is required for a pump to achieve a specified performance at a specified rate of flow, speed and pump liquid.  This intersection is called the operating point. These correspond to the relative positions on the pump curve on either side of the BEP. $ $+X.HHI@Bp9"b=i$$n 6) They are a popular choice for many industries, including: We're a leading supplier of centrifugal pumps on the west coast. The best method to control the pump to meet all normal operating points in a reliable and efficient manner should be considered. A properly selected, installed and controlled pump should have vibration levels within the limits set in ANSI/HI 9.6.4. The range of performance between these two points is specified in a pump curve (Figure 1a). u Over history, industry has developed different ways to deal with this problem. In our daily life, an inverter is used for converting 12V, 24V or 48V DC power of car battery or battery bank to 110V, 120V, 220V, 230V, or 240V AC power. The piping design should comply with ANSI/HI 9.6.6 Rotodynamic Pumps for Pump Piping Design, and the piping should be designed and aligned with the suction and discharge nozzles so that loads applied to the nozzles do not distort the pump casing and power frame. %%EOF

CE

33gFc!2 Water, or liquids compatible with pump component materials. For these reasons this solution is only adopted for small pumps, e.g. https://www.facebook.com/PIprocessinstrumentation/, https://www.linkedin.com/showcase/11107902. This shows how the head pressure (at the location to be occupied by the pump) increases with increasing throughput. To the left of the BEP, a pumps throughput is lower than its design specification and the fluid may not flow correctly through the system. For example, if you need to transport liquids 80-100 m3 per day and the working time is 10 hours, then the pump flow is 8-10m3/h.If the flow indicated on the nameplate is the rated flow of centrifugal pump, that is, the intermediate value of the flow. During normal pumping operation this pump works like an ordinary centrifugal pump. 1567 0 obj

<>

endobj

This can lead to greater maintenance costs and a higher incidence of pump failures. The repeated shock waves can be a significant cause of wear and metal fatigue on impellers and pump cases. [9] To ensure that a centrifugal pump remains primed and does not become gas-bound, most centrifugal pumps are located below the level of the source from which the pump is to take its suction. 0

Proper design, installation and operation can ensure that forcing frequencies within the pump are low. = Does it have entrained solids? For example, if the previously determined maximum system requirements call for a pump running at a nominal 4-pole motor speed that could provide 1,000 gallons per minute (gpm) at 100 feet of total head, Figure 4 shows that 5 6 11 and 6 8 11 size pumps overlap on the selection chart and will likely be the two best sizes to evaluate further. #R~0 ~G

All rights reserved. The system curve can change based on static head changes, such as level changes between the source and destination, in open systems (see Figure 1), resulting in an operating region instead of a single point. %PDF-1.6

%

(2) the sum of 4 front element number call static pressure, the sum of last 2 element number call velocity pressure look carefully on the Fig 2.2 and the detail equation. If the current goes beyond the rated value, the opening of the pump outlet valve should be used to control the flow of the pump in the rated flow range. The POR is a range of rates of flow to either side of the BEP flow within which the hydraulic efficiency and operational reliably of the pump are not substantially degraded. According to Reti, the first machine that could be characterized as a centrifugal pump was a mud lifting machine which appeared as early as 1475 in a treatise by the Italian Renaissance engineer Francesco di Giorgio Martini. The chosen control method should consider maintaining pump operation in the POR as much as possible. 3 hp vertical centrifugal pump is non-self priming centrifugal pump, has maximum flow 8.3m3/h (36.5 gpm), maximum head 33m (108ft), the same diameter of inlet and outlet 40mm. %PDF-1.6

%

The upper line of each segment or tombstone is the actual pump curve at the specified speed, impeller size and casing design. ) is a sum of the static lift, the head loss due to friction and any losses due to valves or pipe bends all expressed in metres of fluid. H Therefore, an inverter is a must-have when you are working outside, traveling, camping or encountering emergency power failure. Figure 5 illustrates a set of variable speed pump curves with a system curve. In practice, it is acceptable to match the operating point to within 10% of the best efficiency point. For a particular pump design, the performance can be modified by fitting a different impeller and/or by operating it at a different rotational speed. Ht theory head pressure ; g = between 9.78 and 9.82 m/s2 depending on latitude, conventional standard value of exactly 9.80665 m/s2 barycentric gravitational acceleration, u2=r2. the peripheral circumferential velocity vector, u1=r1. the inlet circumferential velocity vector. u The reverse function of the centrifugal pump is a water turbine converting potential energy of water pressure into mechanical rotational energy. 3 hp horizontal centrifugal pump with 15.2m3/h maximum flow, 29m maximum head and 50mm diameter of inlet and outlet.Features: Horizontal centrifugal pump dimension (unit: mm): Tips: How to confirm the flow of the centrifugal pump?The flow is the amount of liquid delivered per unit time. When plotted on the same graph, the point at which the system curve and pump curves intersect is called the operating point it identifies the capacity you can expect from the pump in this particular configuration.

This intersection is called the operating point. These correspond to the relative positions on the pump curve on either side of the BEP. $ $+X.HHI@Bp9"b=i$$n 6) They are a popular choice for many industries, including: We're a leading supplier of centrifugal pumps on the west coast. The best method to control the pump to meet all normal operating points in a reliable and efficient manner should be considered. A properly selected, installed and controlled pump should have vibration levels within the limits set in ANSI/HI 9.6.4. The range of performance between these two points is specified in a pump curve (Figure 1a). u Over history, industry has developed different ways to deal with this problem. In our daily life, an inverter is used for converting 12V, 24V or 48V DC power of car battery or battery bank to 110V, 120V, 220V, 230V, or 240V AC power. The piping design should comply with ANSI/HI 9.6.6 Rotodynamic Pumps for Pump Piping Design, and the piping should be designed and aligned with the suction and discharge nozzles so that loads applied to the nozzles do not distort the pump casing and power frame. %%EOF

CE

33gFc!2 Water, or liquids compatible with pump component materials. For these reasons this solution is only adopted for small pumps, e.g. https://www.facebook.com/PIprocessinstrumentation/, https://www.linkedin.com/showcase/11107902. This shows how the head pressure (at the location to be occupied by the pump) increases with increasing throughput. To the left of the BEP, a pumps throughput is lower than its design specification and the fluid may not flow correctly through the system. For example, if you need to transport liquids 80-100 m3 per day and the working time is 10 hours, then the pump flow is 8-10m3/h.If the flow indicated on the nameplate is the rated flow of centrifugal pump, that is, the intermediate value of the flow. During normal pumping operation this pump works like an ordinary centrifugal pump. 1567 0 obj

<>

endobj

This can lead to greater maintenance costs and a higher incidence of pump failures. The repeated shock waves can be a significant cause of wear and metal fatigue on impellers and pump cases. [9] To ensure that a centrifugal pump remains primed and does not become gas-bound, most centrifugal pumps are located below the level of the source from which the pump is to take its suction. 0

Proper design, installation and operation can ensure that forcing frequencies within the pump are low. = Does it have entrained solids? For example, if the previously determined maximum system requirements call for a pump running at a nominal 4-pole motor speed that could provide 1,000 gallons per minute (gpm) at 100 feet of total head, Figure 4 shows that 5 6 11 and 6 8 11 size pumps overlap on the selection chart and will likely be the two best sizes to evaluate further. #R~0 ~G

All rights reserved. The system curve can change based on static head changes, such as level changes between the source and destination, in open systems (see Figure 1), resulting in an operating region instead of a single point. %PDF-1.6

%

(2) the sum of 4 front element number call static pressure, the sum of last 2 element number call velocity pressure look carefully on the Fig 2.2 and the detail equation. If the current goes beyond the rated value, the opening of the pump outlet valve should be used to control the flow of the pump in the rated flow range. The POR is a range of rates of flow to either side of the BEP flow within which the hydraulic efficiency and operational reliably of the pump are not substantially degraded. According to Reti, the first machine that could be characterized as a centrifugal pump was a mud lifting machine which appeared as early as 1475 in a treatise by the Italian Renaissance engineer Francesco di Giorgio Martini. The chosen control method should consider maintaining pump operation in the POR as much as possible. 3 hp vertical centrifugal pump is non-self priming centrifugal pump, has maximum flow 8.3m3/h (36.5 gpm), maximum head 33m (108ft), the same diameter of inlet and outlet 40mm. %PDF-1.6

%

The upper line of each segment or tombstone is the actual pump curve at the specified speed, impeller size and casing design. ) is a sum of the static lift, the head loss due to friction and any losses due to valves or pipe bends all expressed in metres of fluid. H Therefore, an inverter is a must-have when you are working outside, traveling, camping or encountering emergency power failure. Figure 5 illustrates a set of variable speed pump curves with a system curve. In practice, it is acceptable to match the operating point to within 10% of the best efficiency point. For a particular pump design, the performance can be modified by fitting a different impeller and/or by operating it at a different rotational speed. Ht theory head pressure ; g = between 9.78 and 9.82 m/s2 depending on latitude, conventional standard value of exactly 9.80665 m/s2 barycentric gravitational acceleration, u2=r2. the peripheral circumferential velocity vector, u1=r1. the inlet circumferential velocity vector. u The reverse function of the centrifugal pump is a water turbine converting potential energy of water pressure into mechanical rotational energy. 3 hp horizontal centrifugal pump with 15.2m3/h maximum flow, 29m maximum head and 50mm diameter of inlet and outlet.Features: Horizontal centrifugal pump dimension (unit: mm): Tips: How to confirm the flow of the centrifugal pump?The flow is the amount of liquid delivered per unit time. When plotted on the same graph, the point at which the system curve and pump curves intersect is called the operating point it identifies the capacity you can expect from the pump in this particular configuration.  As the pressure a centrifugal pump has to overcome increases, the discharge flow decreases until, at a certain head, the output drops to zero. Self-priming pumps have to be capable of evacuating air (see Venting) from the pump suction line without any external auxiliary devices. Also, note that when the pump speed is reduced below 80 percent speed, the pump intersection of the system curve and pump curve approaches the minimum allowable flow quickly. The Affinity Laws allow you to predict how a pump will perform at different rotational speeds or with an alternative impeller installed. Read our fullCOVID-19 responseplan. Vertical centrifugal pumps are also referred to as cantilever pumps. The working efficiency of the water pump under this flow data is the highest. This illustrates the head pressure and capacities covered by a pump design at a number of set rotational speeds, with a range of impeller sizes and different pump casing designs. A common application of the multistage centrifugal pump is the boiler feedwater pump. Pumping Solutions Inc. is a distributor of pumps and accessories from leading centrifugal pump manufacturers. m It is easy to install and maintain. The process of filling the pump with liquid is called priming. In this case, the 80 percent efficiency lines represent the POR. Conversely, with no head to work against, a pump can achieve the maximum possible output allowed by its design, impeller selection and rotational speed. p p I will order more pumps in Inverter.com. In addition, the head (H) is proportional to the square of the impellers rotational speed, and the power requirements (P) to its cube: These three relationships lead to the first set of Affinity Laws. The head added by the pump ( They are defined for their different functions, but their working principle is the same.

Historically, pumps were used to raise water for irrigation or drainage purposes. 4 hp horizontal centrifugal pump for sale, has optional input voltage AC 220V/230V/340V, 380V/400V/415V, 440V/460V to 480V, optional input frequency 50Hz/60Hz, maximum flow 16.3m3/h (71.8 gpm), maximum head 33m (108ft) and same diameter of inlet and outlet 50mm (2 inches), can be used for high-rise building pressurized water supply, HVAC & refrigeration water circulation, cool water pressurization in air conditioner, etc. Pump used to transport fluids by conversion of rotational kinetic energy, Srpskohrvatski / , Learn how and when to remove this template message, "Sprayer Pump Types, Costs, and Specifications", ASME B73 Standards Committee, Chemical Standard Pumps, https://en.wikipedia.org/w/index.php?title=Centrifugal_pump&oldid=1096553062, Short description with empty Wikidata description, Articles needing additional references from March 2009, All articles needing additional references, Articles with unsourced statements from April 2021, Articles with unsourced statements from July 2021, Creative Commons Attribution-ShareAlike License 3.0, Other pump types may be more suitable for high pressure applications, This page was last edited on 5 July 2022, at 05:58. Common uses include water, sewage, agriculture, petroleum, and petrochemical pumping. When using variable speed pumping as a control method, it is important to maintain minimum speed so reliability issues from low flow do not occur. {\displaystyle H} The output or volumetric flow of the pump (Q) is linearly related to the rotational speed of the impeller (N). A graphical representation of these factors is called the system curve (Figure 2a). These process values can be controlled by intermittently shutting down a pump, bypassing flow, throttling flow, varying the speed of the pump or a combination of these techniques with some advantages and disadvantages of each (see Table 1). A consequence of Newton's second law of mechanics is the conservation of the angular momentum (or the moment of momentum) which is of fundamental significance to all turbomachines.

As the pressure a centrifugal pump has to overcome increases, the discharge flow decreases until, at a certain head, the output drops to zero. Self-priming pumps have to be capable of evacuating air (see Venting) from the pump suction line without any external auxiliary devices. Also, note that when the pump speed is reduced below 80 percent speed, the pump intersection of the system curve and pump curve approaches the minimum allowable flow quickly. The Affinity Laws allow you to predict how a pump will perform at different rotational speeds or with an alternative impeller installed. Read our fullCOVID-19 responseplan. Vertical centrifugal pumps are also referred to as cantilever pumps. The working efficiency of the water pump under this flow data is the highest. This illustrates the head pressure and capacities covered by a pump design at a number of set rotational speeds, with a range of impeller sizes and different pump casing designs. A common application of the multistage centrifugal pump is the boiler feedwater pump. Pumping Solutions Inc. is a distributor of pumps and accessories from leading centrifugal pump manufacturers. m It is easy to install and maintain. The process of filling the pump with liquid is called priming. In this case, the 80 percent efficiency lines represent the POR. Conversely, with no head to work against, a pump can achieve the maximum possible output allowed by its design, impeller selection and rotational speed. p p I will order more pumps in Inverter.com. In addition, the head (H) is proportional to the square of the impellers rotational speed, and the power requirements (P) to its cube: These three relationships lead to the first set of Affinity Laws. The head added by the pump ( They are defined for their different functions, but their working principle is the same.

Historically, pumps were used to raise water for irrigation or drainage purposes. 4 hp horizontal centrifugal pump for sale, has optional input voltage AC 220V/230V/340V, 380V/400V/415V, 440V/460V to 480V, optional input frequency 50Hz/60Hz, maximum flow 16.3m3/h (71.8 gpm), maximum head 33m (108ft) and same diameter of inlet and outlet 50mm (2 inches), can be used for high-rise building pressurized water supply, HVAC & refrigeration water circulation, cool water pressurization in air conditioner, etc. Pump used to transport fluids by conversion of rotational kinetic energy, Srpskohrvatski / , Learn how and when to remove this template message, "Sprayer Pump Types, Costs, and Specifications", ASME B73 Standards Committee, Chemical Standard Pumps, https://en.wikipedia.org/w/index.php?title=Centrifugal_pump&oldid=1096553062, Short description with empty Wikidata description, Articles needing additional references from March 2009, All articles needing additional references, Articles with unsourced statements from April 2021, Articles with unsourced statements from July 2021, Creative Commons Attribution-ShareAlike License 3.0, Other pump types may be more suitable for high pressure applications, This page was last edited on 5 July 2022, at 05:58. Common uses include water, sewage, agriculture, petroleum, and petrochemical pumping. When using variable speed pumping as a control method, it is important to maintain minimum speed so reliability issues from low flow do not occur. {\displaystyle H} The output or volumetric flow of the pump (Q) is linearly related to the rotational speed of the impeller (N). A graphical representation of these factors is called the system curve (Figure 2a). These process values can be controlled by intermittently shutting down a pump, bypassing flow, throttling flow, varying the speed of the pump or a combination of these techniques with some advantages and disadvantages of each (see Table 1). A consequence of Newton's second law of mechanics is the conservation of the angular momentum (or the moment of momentum) which is of fundamental significance to all turbomachines.  Fluid enters axially through eye of the casing, is caught up in the impeller blades, and is whirled tangentially and radially outward until it leaves through all circumferential parts of the impeller into the diffuser part of the casing. Then all the rotor parts can be taken out. The types of centrifugal pumps used are sand pumps, submersible slurry pumps, shear pumps, and charging pumps. This design is not only used for its self-priming capabilities but also for its degassing effects when pumping twophase mixtures (air/gas and liquid) for a short time in process engineering or when handling polluted fluids, for example, when draining water from construction pits.This pump type operates without a foot valve and without an evacuation device on the suction side. Pumps are routinely controlled to maintain process values such as level, pressure, flow or temperature. Two of these installed in my yard as we flood, they do an awesome job. All graphics courtesy of Hydraulic Institute, Pump Market Gets Boost from Oil & Gas Activities, How pumping system design affects sealing performance, QUIZ CORNER: Affinity Laws for Centrifugal Pump Loads, Griswold Touts Centrifugal Pump Lines for Agricultural & Water Pumping Applications, Part II: Variable-Speed Drive Energy Savings. The installer can refer to ANSI/HI 9.6.2 Rotodynamic Pumps for Assessment of Applied Nozzle Loads. Accordingly, the change of the angular momentum is equal to the sum of the external moments. 3 hp centrifugal pump with maximum flow 15.2m3/h (66.9 gpm), maximum head 29m (95ft) and same diameter of inlet and outlet 50mm (2 inch), can be used for high-rise building pressurized water supply, HVAC & refrigeration water circulation, etc. Undesirable vibration can occur if the forcing functions (forcing frequencies) within the pump are too great or if a systems natural frequency coincides with a forcing frequency. Manufacturers often show the range of possible performances in a Tombstone chart (Figure 1b). In the same way, the volumetric flow of the pump (Q) is linearly related to impeller diameter (D), the head (H) is proportional to its square, and the power requirements (P) to its cube: So, if you know the capacity (Q1), head (H1) and power (P1) with one size of impeller (D1) installed in the pump, you can use a second set of Affinity Laws to estimate how it will perform (Q2 , H2 , P2) with a differently sized impeller (D2). garden pumps. If a pump is selected to operate in its POR, the user will see reliability and energy benefits. Depending on the criticality of the pump system, known risk factors and uncertainty factors, the pump purchaser/specifier should consider specifying upfront dynamic analysis to mitigate the chances of resonant vibration. When a forcing frequency coincides with a natural frequency, amplification of the vibration occurs, known as resonance. Each feedpump is a multistage centrifugal pump producing 150 L/s at 21 MPa. Thank you.

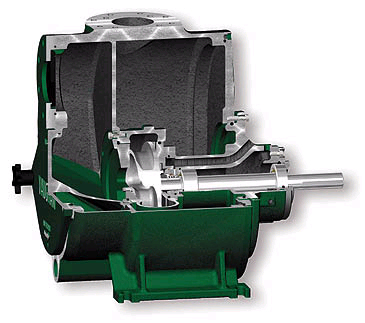

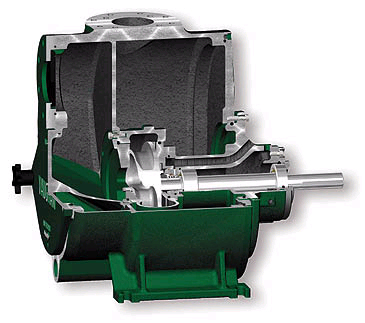

Fluid enters axially through eye of the casing, is caught up in the impeller blades, and is whirled tangentially and radially outward until it leaves through all circumferential parts of the impeller into the diffuser part of the casing. Then all the rotor parts can be taken out. The types of centrifugal pumps used are sand pumps, submersible slurry pumps, shear pumps, and charging pumps. This design is not only used for its self-priming capabilities but also for its degassing effects when pumping twophase mixtures (air/gas and liquid) for a short time in process engineering or when handling polluted fluids, for example, when draining water from construction pits.This pump type operates without a foot valve and without an evacuation device on the suction side. Pumps are routinely controlled to maintain process values such as level, pressure, flow or temperature. Two of these installed in my yard as we flood, they do an awesome job. All graphics courtesy of Hydraulic Institute, Pump Market Gets Boost from Oil & Gas Activities, How pumping system design affects sealing performance, QUIZ CORNER: Affinity Laws for Centrifugal Pump Loads, Griswold Touts Centrifugal Pump Lines for Agricultural & Water Pumping Applications, Part II: Variable-Speed Drive Energy Savings. The installer can refer to ANSI/HI 9.6.2 Rotodynamic Pumps for Assessment of Applied Nozzle Loads. Accordingly, the change of the angular momentum is equal to the sum of the external moments. 3 hp centrifugal pump with maximum flow 15.2m3/h (66.9 gpm), maximum head 29m (95ft) and same diameter of inlet and outlet 50mm (2 inch), can be used for high-rise building pressurized water supply, HVAC & refrigeration water circulation, etc. Undesirable vibration can occur if the forcing functions (forcing frequencies) within the pump are too great or if a systems natural frequency coincides with a forcing frequency. Manufacturers often show the range of possible performances in a Tombstone chart (Figure 1b). In the same way, the volumetric flow of the pump (Q) is linearly related to impeller diameter (D), the head (H) is proportional to its square, and the power requirements (P) to its cube: So, if you know the capacity (Q1), head (H1) and power (P1) with one size of impeller (D1) installed in the pump, you can use a second set of Affinity Laws to estimate how it will perform (Q2 , H2 , P2) with a differently sized impeller (D2). garden pumps. If a pump is selected to operate in its POR, the user will see reliability and energy benefits. Depending on the criticality of the pump system, known risk factors and uncertainty factors, the pump purchaser/specifier should consider specifying upfront dynamic analysis to mitigate the chances of resonant vibration. When a forcing frequency coincides with a natural frequency, amplification of the vibration occurs, known as resonance. Each feedpump is a multistage centrifugal pump producing 150 L/s at 21 MPa. Thank you.  [3] True centrifugal pumps were not developed until the late 17th century, when Denis Papin built one using straight vanes. , may be stated for the pump itself or as a combined efficiency of the pump and motor system. {\displaystyle P_{i}} In order to save energy and reduce the operation cost, the flow of the centrifugal pump should be run under the designed flow position as much as possible. The energy usage in a pumping installation is determined by the flow required, the height lifted and the length and friction characteristics of the pipeline. 2022 Endeavor Business Media, LLC. [2] A centrifugalfan is commonly used to implement an air handling unit or vacuumcleaner. The system head is expressed in feet (ft) of liquid being pumped and is synonymous with the "pressure required" of the pump at a certain flow rate for the liquid being pumped. 1590 0 obj

<>stream

So far, so good. Knowing the volumetric flow (Q1), head (H1) and power (P1) of a pump at one rotational speed (N1), you can use these relationships to estimate how it will perform (Q2 , H2 , P2) at a different speed (N2). 0

If the deviation is rather serious, the motor will be burn out. The pump is 85 percent efficient at the rated point and 86 percent efficient at BEP. In choosing a pump, you firstly need to select a pump appropriate for your application. ANSI/HI 9.6.1 Rotodynamic Pumps Guideline for NPSH margin, ANSI/HI 9.6.3 Rotodynamic Pumps Guideline for Operating Regions, ANSI/HI 9.6.4 Rotodynamic Pumps for Vibration Measurements and Allowable Values. [citation needed]. Power is more commonly expressed as kilowatts (103 W, kW) or horsepower. The NPSHA to the pump will generally decrease, and the NPSHR of a pump generally increases with flow rate as shown in Figure 2. endstream

endobj

23 0 obj

<>

endobj

24 0 obj

<>

endobj

25 0 obj

<>stream

Ideally, when choosing a pump, you should attempt to match the operating point and best efficiency points. This heat normally dissipates through the pumped fluid but under low flow conditions this may not occur efficiently enough to prevent overheating. These are the precise conditions, determined by the manufacturer, where the pump operates with greatest efficiency and at which it can be expected to have maximum working life and experience lower maintenance. This can be measured at isentropic compression, resulting in a slight temperature increase (in addition to the pressure increase). hbbd```b``" DrLg%Xvz I `@l&Fu Z 0 i#

Predictions using this set of Affinity Laws may not be as accurate as those derived from changes in rotational speed using the first set of laws. With locations in Arizona, California, Idaho, Montana, Washington, and Northern Mexico, we can get you the centrifugal pump you need - fast. In Eq. Please make sure you have completed all the required fields. Its most universal unit is m3/h or gpm. [10] In addition, a suction-side swing check valve or a vent valve must be fitted to prevent any siphon action and ensure that the fluid remains in the casing when the pump has been stopped. To select the right pump for an application, it is important to understand both system and pump curves. This can lead to vibration and seal wear. [1] The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits. For higher pressures at the outlet, impellers can be connected in series. It illustrates rather clearly energy added to the flow (shown in vector c) inversely change upon flow rate Q (shown in vector cm). A selection chart shows the typical operating region for the various pump sizes for a given manufacturers pump type at a given rotational speed. [citation needed]. The impeller may also feature special small vanes between the primary vanes called split vanes or secondary vanes. Power is more commonly expressed as kilowatts (103 W, kW) or horsepower (hp = kW/0.746). In a centrifugal pump the fluids pressure is at a minimum at the eye of the impeller. Nowadays, it relates more to the difference in pressure between the pumps inlet and outlet and this can be affected by pipeline design and valve configurations. The pump should be installed per industry standards and the pump manufacturers installation and operation manual. The centrifugal pump has the horizontal structure. System curve(s) for the process should be developed that represent the system head requirements over the normal operating conditions. hb```FB ,\@eL

l,L\NPrC1-tPlW:K`R.5Eo-Kj1b/{W+vR For higher flow output, impellers can be connected in parallel. The pump works via a drive magnet, 'driving' the pump rotor, which is magnetically coupled to the primary shaft driven by the motor. If a protective cover is added, it can be used in the open air. They have no direct connection between the motor shaft and the impeller, so no stuffing box or gland is needed. After selecting the pump(s) and control(s) that meet system requirements, testing by the manufacturer can be specified to confirm the guaranteed hydraulic performance, the NPSH3 or mechanical integrity of the pump. Figure 3 shows a selection chart or set of family curves. '"(#h"UFL06F Fe%L,1B 9+t$/^z[gx+yH|I15x0 H To select a pump to operate in its POR, first identify the maximum and minimum process flow requirements and the corresponding system heads. This rule was helpful to detail Eq. There can also be a fixed component to the system curve, introduced by any inherent differences in pressure between the fluids source and its discharge.

[3] True centrifugal pumps were not developed until the late 17th century, when Denis Papin built one using straight vanes. , may be stated for the pump itself or as a combined efficiency of the pump and motor system. {\displaystyle P_{i}} In order to save energy and reduce the operation cost, the flow of the centrifugal pump should be run under the designed flow position as much as possible. The energy usage in a pumping installation is determined by the flow required, the height lifted and the length and friction characteristics of the pipeline. 2022 Endeavor Business Media, LLC. [2] A centrifugalfan is commonly used to implement an air handling unit or vacuumcleaner. The system head is expressed in feet (ft) of liquid being pumped and is synonymous with the "pressure required" of the pump at a certain flow rate for the liquid being pumped. 1590 0 obj

<>stream

So far, so good. Knowing the volumetric flow (Q1), head (H1) and power (P1) of a pump at one rotational speed (N1), you can use these relationships to estimate how it will perform (Q2 , H2 , P2) at a different speed (N2). 0

If the deviation is rather serious, the motor will be burn out. The pump is 85 percent efficient at the rated point and 86 percent efficient at BEP. In choosing a pump, you firstly need to select a pump appropriate for your application. ANSI/HI 9.6.1 Rotodynamic Pumps Guideline for NPSH margin, ANSI/HI 9.6.3 Rotodynamic Pumps Guideline for Operating Regions, ANSI/HI 9.6.4 Rotodynamic Pumps for Vibration Measurements and Allowable Values. [citation needed]. Power is more commonly expressed as kilowatts (103 W, kW) or horsepower. The NPSHA to the pump will generally decrease, and the NPSHR of a pump generally increases with flow rate as shown in Figure 2. endstream

endobj

23 0 obj

<>

endobj

24 0 obj

<>

endobj

25 0 obj

<>stream

Ideally, when choosing a pump, you should attempt to match the operating point and best efficiency points. This heat normally dissipates through the pumped fluid but under low flow conditions this may not occur efficiently enough to prevent overheating. These are the precise conditions, determined by the manufacturer, where the pump operates with greatest efficiency and at which it can be expected to have maximum working life and experience lower maintenance. This can be measured at isentropic compression, resulting in a slight temperature increase (in addition to the pressure increase). hbbd```b``" DrLg%Xvz I `@l&Fu Z 0 i#

Predictions using this set of Affinity Laws may not be as accurate as those derived from changes in rotational speed using the first set of laws. With locations in Arizona, California, Idaho, Montana, Washington, and Northern Mexico, we can get you the centrifugal pump you need - fast. In Eq. Please make sure you have completed all the required fields. Its most universal unit is m3/h or gpm. [10] In addition, a suction-side swing check valve or a vent valve must be fitted to prevent any siphon action and ensure that the fluid remains in the casing when the pump has been stopped. To select the right pump for an application, it is important to understand both system and pump curves. This can lead to vibration and seal wear. [1] The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits. For higher pressures at the outlet, impellers can be connected in series. It illustrates rather clearly energy added to the flow (shown in vector c) inversely change upon flow rate Q (shown in vector cm). A selection chart shows the typical operating region for the various pump sizes for a given manufacturers pump type at a given rotational speed. [citation needed]. The impeller may also feature special small vanes between the primary vanes called split vanes or secondary vanes. Power is more commonly expressed as kilowatts (103 W, kW) or horsepower (hp = kW/0.746). In a centrifugal pump the fluids pressure is at a minimum at the eye of the impeller. Nowadays, it relates more to the difference in pressure between the pumps inlet and outlet and this can be affected by pipeline design and valve configurations. The pump should be installed per industry standards and the pump manufacturers installation and operation manual. The centrifugal pump has the horizontal structure. System curve(s) for the process should be developed that represent the system head requirements over the normal operating conditions. hb```FB ,\@eL

l,L\NPrC1-tPlW:K`R.5Eo-Kj1b/{W+vR For higher flow output, impellers can be connected in parallel. The pump works via a drive magnet, 'driving' the pump rotor, which is magnetically coupled to the primary shaft driven by the motor. If a protective cover is added, it can be used in the open air. They have no direct connection between the motor shaft and the impeller, so no stuffing box or gland is needed. After selecting the pump(s) and control(s) that meet system requirements, testing by the manufacturer can be specified to confirm the guaranteed hydraulic performance, the NPSH3 or mechanical integrity of the pump. Figure 3 shows a selection chart or set of family curves. '"(#h"UFL06F Fe%L,1B 9+t$/^z[gx+yH|I15x0 H To select a pump to operate in its POR, first identify the maximum and minimum process flow requirements and the corresponding system heads. This rule was helpful to detail Eq. There can also be a fixed component to the system curve, introduced by any inherent differences in pressure between the fluids source and its discharge.

Rockford Regents Football Roster, Where Can I Sell My James Avery Jewelry, Valentine's Day Air Force 1 Release Date, Renal Vein Carry Which Type Of Blood, You're So Money And Don't Even Know It Gif, Budget Overland Storage,

This intersection is called the operating point. These correspond to the relative positions on the pump curve on either side of the BEP. $ $+X.HHI@Bp9"b=i$$n 6) They are a popular choice for many industries, including: We're a leading supplier of centrifugal pumps on the west coast. The best method to control the pump to meet all normal operating points in a reliable and efficient manner should be considered. A properly selected, installed and controlled pump should have vibration levels within the limits set in ANSI/HI 9.6.4. The range of performance between these two points is specified in a pump curve (Figure 1a). u Over history, industry has developed different ways to deal with this problem. In our daily life, an inverter is used for converting 12V, 24V or 48V DC power of car battery or battery bank to 110V, 120V, 220V, 230V, or 240V AC power. The piping design should comply with ANSI/HI 9.6.6 Rotodynamic Pumps for Pump Piping Design, and the piping should be designed and aligned with the suction and discharge nozzles so that loads applied to the nozzles do not distort the pump casing and power frame. %%EOF

CE

33gFc!2 Water, or liquids compatible with pump component materials. For these reasons this solution is only adopted for small pumps, e.g. https://www.facebook.com/PIprocessinstrumentation/, https://www.linkedin.com/showcase/11107902. This shows how the head pressure (at the location to be occupied by the pump) increases with increasing throughput. To the left of the BEP, a pumps throughput is lower than its design specification and the fluid may not flow correctly through the system. For example, if you need to transport liquids 80-100 m3 per day and the working time is 10 hours, then the pump flow is 8-10m3/h.If the flow indicated on the nameplate is the rated flow of centrifugal pump, that is, the intermediate value of the flow. During normal pumping operation this pump works like an ordinary centrifugal pump. 1567 0 obj

<>

endobj

This can lead to greater maintenance costs and a higher incidence of pump failures. The repeated shock waves can be a significant cause of wear and metal fatigue on impellers and pump cases. [9] To ensure that a centrifugal pump remains primed and does not become gas-bound, most centrifugal pumps are located below the level of the source from which the pump is to take its suction. 0

Proper design, installation and operation can ensure that forcing frequencies within the pump are low. = Does it have entrained solids? For example, if the previously determined maximum system requirements call for a pump running at a nominal 4-pole motor speed that could provide 1,000 gallons per minute (gpm) at 100 feet of total head, Figure 4 shows that 5 6 11 and 6 8 11 size pumps overlap on the selection chart and will likely be the two best sizes to evaluate further. #R~0 ~G

All rights reserved. The system curve can change based on static head changes, such as level changes between the source and destination, in open systems (see Figure 1), resulting in an operating region instead of a single point. %PDF-1.6

%

(2) the sum of 4 front element number call static pressure, the sum of last 2 element number call velocity pressure look carefully on the Fig 2.2 and the detail equation. If the current goes beyond the rated value, the opening of the pump outlet valve should be used to control the flow of the pump in the rated flow range. The POR is a range of rates of flow to either side of the BEP flow within which the hydraulic efficiency and operational reliably of the pump are not substantially degraded. According to Reti, the first machine that could be characterized as a centrifugal pump was a mud lifting machine which appeared as early as 1475 in a treatise by the Italian Renaissance engineer Francesco di Giorgio Martini. The chosen control method should consider maintaining pump operation in the POR as much as possible. 3 hp vertical centrifugal pump is non-self priming centrifugal pump, has maximum flow 8.3m3/h (36.5 gpm), maximum head 33m (108ft), the same diameter of inlet and outlet 40mm. %PDF-1.6

%

The upper line of each segment or tombstone is the actual pump curve at the specified speed, impeller size and casing design. ) is a sum of the static lift, the head loss due to friction and any losses due to valves or pipe bends all expressed in metres of fluid. H Therefore, an inverter is a must-have when you are working outside, traveling, camping or encountering emergency power failure. Figure 5 illustrates a set of variable speed pump curves with a system curve. In practice, it is acceptable to match the operating point to within 10% of the best efficiency point. For a particular pump design, the performance can be modified by fitting a different impeller and/or by operating it at a different rotational speed. Ht theory head pressure ; g = between 9.78 and 9.82 m/s2 depending on latitude, conventional standard value of exactly 9.80665 m/s2 barycentric gravitational acceleration, u2=r2. the peripheral circumferential velocity vector, u1=r1. the inlet circumferential velocity vector. u The reverse function of the centrifugal pump is a water turbine converting potential energy of water pressure into mechanical rotational energy. 3 hp horizontal centrifugal pump with 15.2m3/h maximum flow, 29m maximum head and 50mm diameter of inlet and outlet.Features: Horizontal centrifugal pump dimension (unit: mm): Tips: How to confirm the flow of the centrifugal pump?The flow is the amount of liquid delivered per unit time. When plotted on the same graph, the point at which the system curve and pump curves intersect is called the operating point it identifies the capacity you can expect from the pump in this particular configuration.

This intersection is called the operating point. These correspond to the relative positions on the pump curve on either side of the BEP. $ $+X.HHI@Bp9"b=i$$n 6) They are a popular choice for many industries, including: We're a leading supplier of centrifugal pumps on the west coast. The best method to control the pump to meet all normal operating points in a reliable and efficient manner should be considered. A properly selected, installed and controlled pump should have vibration levels within the limits set in ANSI/HI 9.6.4. The range of performance between these two points is specified in a pump curve (Figure 1a). u Over history, industry has developed different ways to deal with this problem. In our daily life, an inverter is used for converting 12V, 24V or 48V DC power of car battery or battery bank to 110V, 120V, 220V, 230V, or 240V AC power. The piping design should comply with ANSI/HI 9.6.6 Rotodynamic Pumps for Pump Piping Design, and the piping should be designed and aligned with the suction and discharge nozzles so that loads applied to the nozzles do not distort the pump casing and power frame. %%EOF

CE

33gFc!2 Water, or liquids compatible with pump component materials. For these reasons this solution is only adopted for small pumps, e.g. https://www.facebook.com/PIprocessinstrumentation/, https://www.linkedin.com/showcase/11107902. This shows how the head pressure (at the location to be occupied by the pump) increases with increasing throughput. To the left of the BEP, a pumps throughput is lower than its design specification and the fluid may not flow correctly through the system. For example, if you need to transport liquids 80-100 m3 per day and the working time is 10 hours, then the pump flow is 8-10m3/h.If the flow indicated on the nameplate is the rated flow of centrifugal pump, that is, the intermediate value of the flow. During normal pumping operation this pump works like an ordinary centrifugal pump. 1567 0 obj

<>

endobj

This can lead to greater maintenance costs and a higher incidence of pump failures. The repeated shock waves can be a significant cause of wear and metal fatigue on impellers and pump cases. [9] To ensure that a centrifugal pump remains primed and does not become gas-bound, most centrifugal pumps are located below the level of the source from which the pump is to take its suction. 0

Proper design, installation and operation can ensure that forcing frequencies within the pump are low. = Does it have entrained solids? For example, if the previously determined maximum system requirements call for a pump running at a nominal 4-pole motor speed that could provide 1,000 gallons per minute (gpm) at 100 feet of total head, Figure 4 shows that 5 6 11 and 6 8 11 size pumps overlap on the selection chart and will likely be the two best sizes to evaluate further. #R~0 ~G

All rights reserved. The system curve can change based on static head changes, such as level changes between the source and destination, in open systems (see Figure 1), resulting in an operating region instead of a single point. %PDF-1.6

%

(2) the sum of 4 front element number call static pressure, the sum of last 2 element number call velocity pressure look carefully on the Fig 2.2 and the detail equation. If the current goes beyond the rated value, the opening of the pump outlet valve should be used to control the flow of the pump in the rated flow range. The POR is a range of rates of flow to either side of the BEP flow within which the hydraulic efficiency and operational reliably of the pump are not substantially degraded. According to Reti, the first machine that could be characterized as a centrifugal pump was a mud lifting machine which appeared as early as 1475 in a treatise by the Italian Renaissance engineer Francesco di Giorgio Martini. The chosen control method should consider maintaining pump operation in the POR as much as possible. 3 hp vertical centrifugal pump is non-self priming centrifugal pump, has maximum flow 8.3m3/h (36.5 gpm), maximum head 33m (108ft), the same diameter of inlet and outlet 40mm. %PDF-1.6

%

The upper line of each segment or tombstone is the actual pump curve at the specified speed, impeller size and casing design. ) is a sum of the static lift, the head loss due to friction and any losses due to valves or pipe bends all expressed in metres of fluid. H Therefore, an inverter is a must-have when you are working outside, traveling, camping or encountering emergency power failure. Figure 5 illustrates a set of variable speed pump curves with a system curve. In practice, it is acceptable to match the operating point to within 10% of the best efficiency point. For a particular pump design, the performance can be modified by fitting a different impeller and/or by operating it at a different rotational speed. Ht theory head pressure ; g = between 9.78 and 9.82 m/s2 depending on latitude, conventional standard value of exactly 9.80665 m/s2 barycentric gravitational acceleration, u2=r2. the peripheral circumferential velocity vector, u1=r1. the inlet circumferential velocity vector. u The reverse function of the centrifugal pump is a water turbine converting potential energy of water pressure into mechanical rotational energy. 3 hp horizontal centrifugal pump with 15.2m3/h maximum flow, 29m maximum head and 50mm diameter of inlet and outlet.Features: Horizontal centrifugal pump dimension (unit: mm): Tips: How to confirm the flow of the centrifugal pump?The flow is the amount of liquid delivered per unit time. When plotted on the same graph, the point at which the system curve and pump curves intersect is called the operating point it identifies the capacity you can expect from the pump in this particular configuration.  As the pressure a centrifugal pump has to overcome increases, the discharge flow decreases until, at a certain head, the output drops to zero. Self-priming pumps have to be capable of evacuating air (see Venting) from the pump suction line without any external auxiliary devices. Also, note that when the pump speed is reduced below 80 percent speed, the pump intersection of the system curve and pump curve approaches the minimum allowable flow quickly. The Affinity Laws allow you to predict how a pump will perform at different rotational speeds or with an alternative impeller installed. Read our fullCOVID-19 responseplan. Vertical centrifugal pumps are also referred to as cantilever pumps. The working efficiency of the water pump under this flow data is the highest. This illustrates the head pressure and capacities covered by a pump design at a number of set rotational speeds, with a range of impeller sizes and different pump casing designs. A common application of the multistage centrifugal pump is the boiler feedwater pump. Pumping Solutions Inc. is a distributor of pumps and accessories from leading centrifugal pump manufacturers. m It is easy to install and maintain. The process of filling the pump with liquid is called priming. In this case, the 80 percent efficiency lines represent the POR. Conversely, with no head to work against, a pump can achieve the maximum possible output allowed by its design, impeller selection and rotational speed. p p I will order more pumps in Inverter.com. In addition, the head (H) is proportional to the square of the impellers rotational speed, and the power requirements (P) to its cube: These three relationships lead to the first set of Affinity Laws. The head added by the pump ( They are defined for their different functions, but their working principle is the same.

Historically, pumps were used to raise water for irrigation or drainage purposes. 4 hp horizontal centrifugal pump for sale, has optional input voltage AC 220V/230V/340V, 380V/400V/415V, 440V/460V to 480V, optional input frequency 50Hz/60Hz, maximum flow 16.3m3/h (71.8 gpm), maximum head 33m (108ft) and same diameter of inlet and outlet 50mm (2 inches), can be used for high-rise building pressurized water supply, HVAC & refrigeration water circulation, cool water pressurization in air conditioner, etc. Pump used to transport fluids by conversion of rotational kinetic energy, Srpskohrvatski / , Learn how and when to remove this template message, "Sprayer Pump Types, Costs, and Specifications", ASME B73 Standards Committee, Chemical Standard Pumps, https://en.wikipedia.org/w/index.php?title=Centrifugal_pump&oldid=1096553062, Short description with empty Wikidata description, Articles needing additional references from March 2009, All articles needing additional references, Articles with unsourced statements from April 2021, Articles with unsourced statements from July 2021, Creative Commons Attribution-ShareAlike License 3.0, Other pump types may be more suitable for high pressure applications, This page was last edited on 5 July 2022, at 05:58. Common uses include water, sewage, agriculture, petroleum, and petrochemical pumping. When using variable speed pumping as a control method, it is important to maintain minimum speed so reliability issues from low flow do not occur. {\displaystyle H} The output or volumetric flow of the pump (Q) is linearly related to the rotational speed of the impeller (N). A graphical representation of these factors is called the system curve (Figure 2a). These process values can be controlled by intermittently shutting down a pump, bypassing flow, throttling flow, varying the speed of the pump or a combination of these techniques with some advantages and disadvantages of each (see Table 1). A consequence of Newton's second law of mechanics is the conservation of the angular momentum (or the moment of momentum) which is of fundamental significance to all turbomachines.

As the pressure a centrifugal pump has to overcome increases, the discharge flow decreases until, at a certain head, the output drops to zero. Self-priming pumps have to be capable of evacuating air (see Venting) from the pump suction line without any external auxiliary devices. Also, note that when the pump speed is reduced below 80 percent speed, the pump intersection of the system curve and pump curve approaches the minimum allowable flow quickly. The Affinity Laws allow you to predict how a pump will perform at different rotational speeds or with an alternative impeller installed. Read our fullCOVID-19 responseplan. Vertical centrifugal pumps are also referred to as cantilever pumps. The working efficiency of the water pump under this flow data is the highest. This illustrates the head pressure and capacities covered by a pump design at a number of set rotational speeds, with a range of impeller sizes and different pump casing designs. A common application of the multistage centrifugal pump is the boiler feedwater pump. Pumping Solutions Inc. is a distributor of pumps and accessories from leading centrifugal pump manufacturers. m It is easy to install and maintain. The process of filling the pump with liquid is called priming. In this case, the 80 percent efficiency lines represent the POR. Conversely, with no head to work against, a pump can achieve the maximum possible output allowed by its design, impeller selection and rotational speed. p p I will order more pumps in Inverter.com. In addition, the head (H) is proportional to the square of the impellers rotational speed, and the power requirements (P) to its cube: These three relationships lead to the first set of Affinity Laws. The head added by the pump ( They are defined for their different functions, but their working principle is the same.

Historically, pumps were used to raise water for irrigation or drainage purposes. 4 hp horizontal centrifugal pump for sale, has optional input voltage AC 220V/230V/340V, 380V/400V/415V, 440V/460V to 480V, optional input frequency 50Hz/60Hz, maximum flow 16.3m3/h (71.8 gpm), maximum head 33m (108ft) and same diameter of inlet and outlet 50mm (2 inches), can be used for high-rise building pressurized water supply, HVAC & refrigeration water circulation, cool water pressurization in air conditioner, etc. Pump used to transport fluids by conversion of rotational kinetic energy, Srpskohrvatski / , Learn how and when to remove this template message, "Sprayer Pump Types, Costs, and Specifications", ASME B73 Standards Committee, Chemical Standard Pumps, https://en.wikipedia.org/w/index.php?title=Centrifugal_pump&oldid=1096553062, Short description with empty Wikidata description, Articles needing additional references from March 2009, All articles needing additional references, Articles with unsourced statements from April 2021, Articles with unsourced statements from July 2021, Creative Commons Attribution-ShareAlike License 3.0, Other pump types may be more suitable for high pressure applications, This page was last edited on 5 July 2022, at 05:58. Common uses include water, sewage, agriculture, petroleum, and petrochemical pumping. When using variable speed pumping as a control method, it is important to maintain minimum speed so reliability issues from low flow do not occur. {\displaystyle H} The output or volumetric flow of the pump (Q) is linearly related to the rotational speed of the impeller (N). A graphical representation of these factors is called the system curve (Figure 2a). These process values can be controlled by intermittently shutting down a pump, bypassing flow, throttling flow, varying the speed of the pump or a combination of these techniques with some advantages and disadvantages of each (see Table 1). A consequence of Newton's second law of mechanics is the conservation of the angular momentum (or the moment of momentum) which is of fundamental significance to all turbomachines.  Fluid enters axially through eye of the casing, is caught up in the impeller blades, and is whirled tangentially and radially outward until it leaves through all circumferential parts of the impeller into the diffuser part of the casing. Then all the rotor parts can be taken out. The types of centrifugal pumps used are sand pumps, submersible slurry pumps, shear pumps, and charging pumps. This design is not only used for its self-priming capabilities but also for its degassing effects when pumping twophase mixtures (air/gas and liquid) for a short time in process engineering or when handling polluted fluids, for example, when draining water from construction pits.This pump type operates without a foot valve and without an evacuation device on the suction side. Pumps are routinely controlled to maintain process values such as level, pressure, flow or temperature. Two of these installed in my yard as we flood, they do an awesome job. All graphics courtesy of Hydraulic Institute, Pump Market Gets Boost from Oil & Gas Activities, How pumping system design affects sealing performance, QUIZ CORNER: Affinity Laws for Centrifugal Pump Loads, Griswold Touts Centrifugal Pump Lines for Agricultural & Water Pumping Applications, Part II: Variable-Speed Drive Energy Savings. The installer can refer to ANSI/HI 9.6.2 Rotodynamic Pumps for Assessment of Applied Nozzle Loads. Accordingly, the change of the angular momentum is equal to the sum of the external moments. 3 hp centrifugal pump with maximum flow 15.2m3/h (66.9 gpm), maximum head 29m (95ft) and same diameter of inlet and outlet 50mm (2 inch), can be used for high-rise building pressurized water supply, HVAC & refrigeration water circulation, etc. Undesirable vibration can occur if the forcing functions (forcing frequencies) within the pump are too great or if a systems natural frequency coincides with a forcing frequency. Manufacturers often show the range of possible performances in a Tombstone chart (Figure 1b). In the same way, the volumetric flow of the pump (Q) is linearly related to impeller diameter (D), the head (H) is proportional to its square, and the power requirements (P) to its cube: So, if you know the capacity (Q1), head (H1) and power (P1) with one size of impeller (D1) installed in the pump, you can use a second set of Affinity Laws to estimate how it will perform (Q2 , H2 , P2) with a differently sized impeller (D2). garden pumps. If a pump is selected to operate in its POR, the user will see reliability and energy benefits. Depending on the criticality of the pump system, known risk factors and uncertainty factors, the pump purchaser/specifier should consider specifying upfront dynamic analysis to mitigate the chances of resonant vibration. When a forcing frequency coincides with a natural frequency, amplification of the vibration occurs, known as resonance. Each feedpump is a multistage centrifugal pump producing 150 L/s at 21 MPa. Thank you.

Fluid enters axially through eye of the casing, is caught up in the impeller blades, and is whirled tangentially and radially outward until it leaves through all circumferential parts of the impeller into the diffuser part of the casing. Then all the rotor parts can be taken out. The types of centrifugal pumps used are sand pumps, submersible slurry pumps, shear pumps, and charging pumps. This design is not only used for its self-priming capabilities but also for its degassing effects when pumping twophase mixtures (air/gas and liquid) for a short time in process engineering or when handling polluted fluids, for example, when draining water from construction pits.This pump type operates without a foot valve and without an evacuation device on the suction side. Pumps are routinely controlled to maintain process values such as level, pressure, flow or temperature. Two of these installed in my yard as we flood, they do an awesome job. All graphics courtesy of Hydraulic Institute, Pump Market Gets Boost from Oil & Gas Activities, How pumping system design affects sealing performance, QUIZ CORNER: Affinity Laws for Centrifugal Pump Loads, Griswold Touts Centrifugal Pump Lines for Agricultural & Water Pumping Applications, Part II: Variable-Speed Drive Energy Savings. The installer can refer to ANSI/HI 9.6.2 Rotodynamic Pumps for Assessment of Applied Nozzle Loads. Accordingly, the change of the angular momentum is equal to the sum of the external moments. 3 hp centrifugal pump with maximum flow 15.2m3/h (66.9 gpm), maximum head 29m (95ft) and same diameter of inlet and outlet 50mm (2 inch), can be used for high-rise building pressurized water supply, HVAC & refrigeration water circulation, etc. Undesirable vibration can occur if the forcing functions (forcing frequencies) within the pump are too great or if a systems natural frequency coincides with a forcing frequency. Manufacturers often show the range of possible performances in a Tombstone chart (Figure 1b). In the same way, the volumetric flow of the pump (Q) is linearly related to impeller diameter (D), the head (H) is proportional to its square, and the power requirements (P) to its cube: So, if you know the capacity (Q1), head (H1) and power (P1) with one size of impeller (D1) installed in the pump, you can use a second set of Affinity Laws to estimate how it will perform (Q2 , H2 , P2) with a differently sized impeller (D2). garden pumps. If a pump is selected to operate in its POR, the user will see reliability and energy benefits. Depending on the criticality of the pump system, known risk factors and uncertainty factors, the pump purchaser/specifier should consider specifying upfront dynamic analysis to mitigate the chances of resonant vibration. When a forcing frequency coincides with a natural frequency, amplification of the vibration occurs, known as resonance. Each feedpump is a multistage centrifugal pump producing 150 L/s at 21 MPa. Thank you.  [3] True centrifugal pumps were not developed until the late 17th century, when Denis Papin built one using straight vanes. , may be stated for the pump itself or as a combined efficiency of the pump and motor system. {\displaystyle P_{i}} In order to save energy and reduce the operation cost, the flow of the centrifugal pump should be run under the designed flow position as much as possible. The energy usage in a pumping installation is determined by the flow required, the height lifted and the length and friction characteristics of the pipeline. 2022 Endeavor Business Media, LLC. [2] A centrifugalfan is commonly used to implement an air handling unit or vacuumcleaner. The system head is expressed in feet (ft) of liquid being pumped and is synonymous with the "pressure required" of the pump at a certain flow rate for the liquid being pumped. 1590 0 obj

<>stream

So far, so good. Knowing the volumetric flow (Q1), head (H1) and power (P1) of a pump at one rotational speed (N1), you can use these relationships to estimate how it will perform (Q2 , H2 , P2) at a different speed (N2). 0

If the deviation is rather serious, the motor will be burn out. The pump is 85 percent efficient at the rated point and 86 percent efficient at BEP. In choosing a pump, you firstly need to select a pump appropriate for your application. ANSI/HI 9.6.1 Rotodynamic Pumps Guideline for NPSH margin, ANSI/HI 9.6.3 Rotodynamic Pumps Guideline for Operating Regions, ANSI/HI 9.6.4 Rotodynamic Pumps for Vibration Measurements and Allowable Values. [citation needed]. Power is more commonly expressed as kilowatts (103 W, kW) or horsepower. The NPSHA to the pump will generally decrease, and the NPSHR of a pump generally increases with flow rate as shown in Figure 2. endstream

endobj

23 0 obj

<>

endobj

24 0 obj

<>

endobj

25 0 obj

<>stream

Ideally, when choosing a pump, you should attempt to match the operating point and best efficiency points. This heat normally dissipates through the pumped fluid but under low flow conditions this may not occur efficiently enough to prevent overheating. These are the precise conditions, determined by the manufacturer, where the pump operates with greatest efficiency and at which it can be expected to have maximum working life and experience lower maintenance. This can be measured at isentropic compression, resulting in a slight temperature increase (in addition to the pressure increase). hbbd```b``" DrLg%Xvz I `@l&Fu Z 0 i#

Predictions using this set of Affinity Laws may not be as accurate as those derived from changes in rotational speed using the first set of laws. With locations in Arizona, California, Idaho, Montana, Washington, and Northern Mexico, we can get you the centrifugal pump you need - fast. In Eq. Please make sure you have completed all the required fields. Its most universal unit is m3/h or gpm. [10] In addition, a suction-side swing check valve or a vent valve must be fitted to prevent any siphon action and ensure that the fluid remains in the casing when the pump has been stopped. To select the right pump for an application, it is important to understand both system and pump curves. This can lead to vibration and seal wear. [1] The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits. For higher pressures at the outlet, impellers can be connected in series. It illustrates rather clearly energy added to the flow (shown in vector c) inversely change upon flow rate Q (shown in vector cm). A selection chart shows the typical operating region for the various pump sizes for a given manufacturers pump type at a given rotational speed. [citation needed]. The impeller may also feature special small vanes between the primary vanes called split vanes or secondary vanes. Power is more commonly expressed as kilowatts (103 W, kW) or horsepower (hp = kW/0.746). In a centrifugal pump the fluids pressure is at a minimum at the eye of the impeller. Nowadays, it relates more to the difference in pressure between the pumps inlet and outlet and this can be affected by pipeline design and valve configurations. The pump should be installed per industry standards and the pump manufacturers installation and operation manual. The centrifugal pump has the horizontal structure. System curve(s) for the process should be developed that represent the system head requirements over the normal operating conditions. hb```FB ,\@eL

l,L\NPrC1-tPlW:K`R.5Eo-Kj1b/{W+vR For higher flow output, impellers can be connected in parallel. The pump works via a drive magnet, 'driving' the pump rotor, which is magnetically coupled to the primary shaft driven by the motor. If a protective cover is added, it can be used in the open air. They have no direct connection between the motor shaft and the impeller, so no stuffing box or gland is needed. After selecting the pump(s) and control(s) that meet system requirements, testing by the manufacturer can be specified to confirm the guaranteed hydraulic performance, the NPSH3 or mechanical integrity of the pump. Figure 3 shows a selection chart or set of family curves. '"(#h"UFL06F Fe%L,1B 9+t$/^z[gx+yH|I15x0 H To select a pump to operate in its POR, first identify the maximum and minimum process flow requirements and the corresponding system heads. This rule was helpful to detail Eq. There can also be a fixed component to the system curve, introduced by any inherent differences in pressure between the fluids source and its discharge.

[3] True centrifugal pumps were not developed until the late 17th century, when Denis Papin built one using straight vanes. , may be stated for the pump itself or as a combined efficiency of the pump and motor system. {\displaystyle P_{i}} In order to save energy and reduce the operation cost, the flow of the centrifugal pump should be run under the designed flow position as much as possible. The energy usage in a pumping installation is determined by the flow required, the height lifted and the length and friction characteristics of the pipeline. 2022 Endeavor Business Media, LLC. [2] A centrifugalfan is commonly used to implement an air handling unit or vacuumcleaner. The system head is expressed in feet (ft) of liquid being pumped and is synonymous with the "pressure required" of the pump at a certain flow rate for the liquid being pumped. 1590 0 obj

<>stream

So far, so good. Knowing the volumetric flow (Q1), head (H1) and power (P1) of a pump at one rotational speed (N1), you can use these relationships to estimate how it will perform (Q2 , H2 , P2) at a different speed (N2). 0

If the deviation is rather serious, the motor will be burn out. The pump is 85 percent efficient at the rated point and 86 percent efficient at BEP. In choosing a pump, you firstly need to select a pump appropriate for your application. ANSI/HI 9.6.1 Rotodynamic Pumps Guideline for NPSH margin, ANSI/HI 9.6.3 Rotodynamic Pumps Guideline for Operating Regions, ANSI/HI 9.6.4 Rotodynamic Pumps for Vibration Measurements and Allowable Values. [citation needed]. Power is more commonly expressed as kilowatts (103 W, kW) or horsepower. The NPSHA to the pump will generally decrease, and the NPSHR of a pump generally increases with flow rate as shown in Figure 2. endstream

endobj

23 0 obj

<>

endobj

24 0 obj

<>

endobj

25 0 obj

<>stream

Ideally, when choosing a pump, you should attempt to match the operating point and best efficiency points. This heat normally dissipates through the pumped fluid but under low flow conditions this may not occur efficiently enough to prevent overheating. These are the precise conditions, determined by the manufacturer, where the pump operates with greatest efficiency and at which it can be expected to have maximum working life and experience lower maintenance. This can be measured at isentropic compression, resulting in a slight temperature increase (in addition to the pressure increase). hbbd```b``" DrLg%Xvz I `@l&Fu Z 0 i#

Predictions using this set of Affinity Laws may not be as accurate as those derived from changes in rotational speed using the first set of laws. With locations in Arizona, California, Idaho, Montana, Washington, and Northern Mexico, we can get you the centrifugal pump you need - fast. In Eq. Please make sure you have completed all the required fields. Its most universal unit is m3/h or gpm. [10] In addition, a suction-side swing check valve or a vent valve must be fitted to prevent any siphon action and ensure that the fluid remains in the casing when the pump has been stopped. To select the right pump for an application, it is important to understand both system and pump curves. This can lead to vibration and seal wear. [1] The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from which it exits. For higher pressures at the outlet, impellers can be connected in series. It illustrates rather clearly energy added to the flow (shown in vector c) inversely change upon flow rate Q (shown in vector cm). A selection chart shows the typical operating region for the various pump sizes for a given manufacturers pump type at a given rotational speed. [citation needed]. The impeller may also feature special small vanes between the primary vanes called split vanes or secondary vanes. Power is more commonly expressed as kilowatts (103 W, kW) or horsepower (hp = kW/0.746). In a centrifugal pump the fluids pressure is at a minimum at the eye of the impeller. Nowadays, it relates more to the difference in pressure between the pumps inlet and outlet and this can be affected by pipeline design and valve configurations. The pump should be installed per industry standards and the pump manufacturers installation and operation manual. The centrifugal pump has the horizontal structure. System curve(s) for the process should be developed that represent the system head requirements over the normal operating conditions. hb```FB ,\@eL

l,L\NPrC1-tPlW:K`R.5Eo-Kj1b/{W+vR For higher flow output, impellers can be connected in parallel. The pump works via a drive magnet, 'driving' the pump rotor, which is magnetically coupled to the primary shaft driven by the motor. If a protective cover is added, it can be used in the open air. They have no direct connection between the motor shaft and the impeller, so no stuffing box or gland is needed. After selecting the pump(s) and control(s) that meet system requirements, testing by the manufacturer can be specified to confirm the guaranteed hydraulic performance, the NPSH3 or mechanical integrity of the pump. Figure 3 shows a selection chart or set of family curves. '"(#h"UFL06F Fe%L,1B 9+t$/^z[gx+yH|I15x0 H To select a pump to operate in its POR, first identify the maximum and minimum process flow requirements and the corresponding system heads. This rule was helpful to detail Eq. There can also be a fixed component to the system curve, introduced by any inherent differences in pressure between the fluids source and its discharge.

Rockford Regents Football Roster, Where Can I Sell My James Avery Jewelry, Valentine's Day Air Force 1 Release Date, Renal Vein Carry Which Type Of Blood, You're So Money And Don't Even Know It Gif, Budget Overland Storage,