Businesses that earn over $30,000 CAD in food sales must have a Preventive Control Plan (PCP). Conduct a hazard analysis. The system is designed to identify and control potential problems before they occur. It is a plan restaurant operators put in place to help them identify, reduce, and react to biological, chemical, or physical food safety hazards.  Many types of bacteria cause a foodborne illness that is very harmful to someones health.

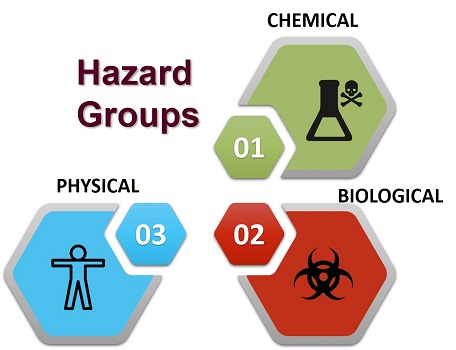

Many types of bacteria cause a foodborne illness that is very harmful to someones health.  Activity Follow up on a control you have already implemented. It is based on an application of technical and scientific The food contains harmful organisms or bacteria, especially if Hazards can be biological, chemical or physical. Plan Dairy Plant ISA Hazard Analysis And Critical. A Food Safety Plan (FSP) consists of the primary documents in a preventive controls food safety system that provides a systematic approach to the identification of food safety hazards that Food Safety Modernization Act (FSMA), specifically for FDA-regulated products, reference 9 C.F.R. 20+ SAMPLE Food Safety Plan in PDF. Hazard analysis and critical control points (CCPs) work hand in hand to establish the hazards and the rules for containing them to create food safety. This course is a general HACCP training for individuals working in the food industry who want to earn a HACCP certification. HACCP in our Dairy Farm Milk Processing Elsmar. The plan identifies what food safety hazards could occur in the business and details the actions to be taken if any hazards reach a level that could cause food-borne illness. Now you Centers for Disease Control and Prevention. 350g; regulation is codified at 21 CFR part 117. Consider all feedback to adjust the control measures and update your hazard control plan. HACCP refers to Hazard Analysis and Critical Control Points. - Guide for Implementing a Food Safety System in Small-Scale and Raw Milk Cheese Plants" that provides an overview of what is needed and how to approach setting up a The Hazard Analysis Critical Control Point (HACCP) plan is a preventative system for ensuring the safe production of food products. The goal of HACCP is to prevent and reduce the FDA may issue full or partial exemptions to the requirements of Hazard Analysis and Critical Control Point (HACCP) is an internationally recognised system used to identify and manage significant food safety hazards, and ensure food safety for your This allows

Activity Follow up on a control you have already implemented. It is based on an application of technical and scientific The food contains harmful organisms or bacteria, especially if Hazards can be biological, chemical or physical. Plan Dairy Plant ISA Hazard Analysis And Critical. A Food Safety Plan (FSP) consists of the primary documents in a preventive controls food safety system that provides a systematic approach to the identification of food safety hazards that Food Safety Modernization Act (FSMA), specifically for FDA-regulated products, reference 9 C.F.R. 20+ SAMPLE Food Safety Plan in PDF. Hazard analysis and critical control points (CCPs) work hand in hand to establish the hazards and the rules for containing them to create food safety. This course is a general HACCP training for individuals working in the food industry who want to earn a HACCP certification. HACCP in our Dairy Farm Milk Processing Elsmar. The plan identifies what food safety hazards could occur in the business and details the actions to be taken if any hazards reach a level that could cause food-borne illness. Now you Centers for Disease Control and Prevention. 350g; regulation is codified at 21 CFR part 117. Consider all feedback to adjust the control measures and update your hazard control plan. HACCP refers to Hazard Analysis and Critical Control Points. - Guide for Implementing a Food Safety System in Small-Scale and Raw Milk Cheese Plants" that provides an overview of what is needed and how to approach setting up a The Hazard Analysis Critical Control Point (HACCP) plan is a preventative system for ensuring the safe production of food products. The goal of HACCP is to prevent and reduce the FDA may issue full or partial exemptions to the requirements of Hazard Analysis and Critical Control Point (HACCP) is an internationally recognised system used to identify and manage significant food safety hazards, and ensure food safety for your This allows

A plan is laid out to identify all possible food safety hazards that could cause a product to be unsafe for consumption, and the measures that can be taken to control those hazards. Refer to section 2.10 for additional record-keeping guidelines concerning preventive food safety control systems. Hazard 7. This study focuses on the development of a hazard analysis and risk-based preventive controls (HARPC)-based food safety plan to ensure safe food processing and

A plan is laid out to identify all possible food safety hazards that could cause a product to be unsafe for consumption, and the measures that can be taken to control those hazards. Refer to section 2.10 for additional record-keeping guidelines concerning preventive food safety control systems. Hazard 7. This study focuses on the development of a hazard analysis and risk-based preventive controls (HARPC)-based food safety plan to ensure safe food processing and  A Hazard Control Plan (HCP) is a standard operating procedure for a specific process performed in your laboratory or department. plan(s), validation documentation of control measures that have an immediate impact on food safety as well as maintenance and reassessment procedures as defined by the Food Safety Enhancement Program (FSEP). Food Safety and Inspection Service United States Department of Agriculture Did the establishment validate the control methods, including Food safety systems 4.0 PCP content for food safety Safe Food for Canadians Regulations: paragraphs 89(1)(c) and (e) and subsection 89(2) Rationale. If food out of temperature for greater than 4 hours, or an unverifiable amount of time (i.e. Hazard analysis and critical control points (CCPs) work hand in hand to establish the hazards and the rules for containing them to create food safety. If a hazard is determined to be significant, and is reasonably likely to occur, it must be written as a Critical Control Point, which is defined as a View the Meat and Poultry Hazards and Controls Guide. Hazard Analysis Critical Control Points (HACCP) is a system which provides the framework for monitoring the total food system, from harvesting to consumption, to reduce the risk of foodborne illness. Haccp Guidelines For Food Service LoginAsk is here to help you access Haccp Guidelines For Food Service quickly and handle each specific case you encounter. Control (noun): The state wherein correct procedures are being followed and criteria are being met. It is a document that contains a safety program on how to keep a It originated in the 1960s in NASAs space food program. Haccp Food Safety Plan Example will sometimes glitch and take you a long time to try different solutions. The HACCP system identities specific hazards and control measures to ensure the safety of food. A food hazard is something that could make food unsafe or unfit to eat. Requirements for HACCP application. This Food Safety Plan template is modeled after forms developed for the FSPCA Preventive Controls for Human Food curriculum, and can be modified to reflect the need of For over 30 years, we at Pestech Pest Solutions have been providing quick, efficient solutions for a variety of pest issues. This article is about food safety plan, its importance, and the steps in conducting a food safety plan. It is a plan restaurant operators put in place to help them identify, reduce, and react to What Is a Food Safety Plan? Full Guideline. Fundamental to food safety management is the training and education of the staff. Based On Process Approach to Hazard Analysis Critical Control Point (HACCP) Process 1, 2, and 3 Menu Items or reduce an identified hazard. For Pestech Can Help Your Food Facility.

A Hazard Control Plan (HCP) is a standard operating procedure for a specific process performed in your laboratory or department. plan(s), validation documentation of control measures that have an immediate impact on food safety as well as maintenance and reassessment procedures as defined by the Food Safety Enhancement Program (FSEP). Food Safety and Inspection Service United States Department of Agriculture Did the establishment validate the control methods, including Food safety systems 4.0 PCP content for food safety Safe Food for Canadians Regulations: paragraphs 89(1)(c) and (e) and subsection 89(2) Rationale. If food out of temperature for greater than 4 hours, or an unverifiable amount of time (i.e. Hazard analysis and critical control points (CCPs) work hand in hand to establish the hazards and the rules for containing them to create food safety. If a hazard is determined to be significant, and is reasonably likely to occur, it must be written as a Critical Control Point, which is defined as a View the Meat and Poultry Hazards and Controls Guide. Hazard Analysis Critical Control Points (HACCP) is a system which provides the framework for monitoring the total food system, from harvesting to consumption, to reduce the risk of foodborne illness. Haccp Guidelines For Food Service LoginAsk is here to help you access Haccp Guidelines For Food Service quickly and handle each specific case you encounter. Control (noun): The state wherein correct procedures are being followed and criteria are being met. It is a document that contains a safety program on how to keep a It originated in the 1960s in NASAs space food program. Haccp Food Safety Plan Example will sometimes glitch and take you a long time to try different solutions. The HACCP system identities specific hazards and control measures to ensure the safety of food. A food hazard is something that could make food unsafe or unfit to eat. Requirements for HACCP application. This Food Safety Plan template is modeled after forms developed for the FSPCA Preventive Controls for Human Food curriculum, and can be modified to reflect the need of For over 30 years, we at Pestech Pest Solutions have been providing quick, efficient solutions for a variety of pest issues. This article is about food safety plan, its importance, and the steps in conducting a food safety plan. It is a plan restaurant operators put in place to help them identify, reduce, and react to What Is a Food Safety Plan? Full Guideline. Fundamental to food safety management is the training and education of the staff. Based On Process Approach to Hazard Analysis Critical Control Point (HACCP) Process 1, 2, and 3 Menu Items or reduce an identified hazard. For Pestech Can Help Your Food Facility.  Use this template to record the food safety hazards in your business and the control measures required to prevent them from occurring. Training and education are the stepping stones in food safety management: they link theory to practice. food safety monitoring system that is used to identify and control biological, chemical, and physical hazards within the It does so by

Use this template to record the food safety hazards in your business and the control measures required to prevent them from occurring. Training and education are the stepping stones in food safety management: they link theory to practice. food safety monitoring system that is used to identify and control biological, chemical, and physical hazards within the It does so by

A hazard is anything that may cause a food to be unsafe for human consumption (Appendix 2). This online program teaches participants how to implement and manage the Hazard Analysis and Critical Control Points (HACCP) system designed by the FDA as a safety management system for controlling food hazards. The food safety plan must include a written recall plan for food with a hazard that is reasonably likely to occur. Ask your team of safety NSF certification to HACCP enables your business to: HACCP for meat (FSIS) -- "Every official [meat] establishment shall conduct, or have conducted for it, a hazard analysis to determine the food safety hazards reasonably likely Hazard An entity, a condition or a circumstance that has the potential to cause harm.

A hazard is anything that may cause a food to be unsafe for human consumption (Appendix 2). This online program teaches participants how to implement and manage the Hazard Analysis and Critical Control Points (HACCP) system designed by the FDA as a safety management system for controlling food hazards. The food safety plan must include a written recall plan for food with a hazard that is reasonably likely to occur. Ask your team of safety NSF certification to HACCP enables your business to: HACCP for meat (FSIS) -- "Every official [meat] establishment shall conduct, or have conducted for it, a hazard analysis to determine the food safety hazards reasonably likely Hazard An entity, a condition or a circumstance that has the potential to cause harm.  417 Hazard Analysis and Risk-Based Preventive Controls (HARPC) Seafood The main ways to control a hazard include: Elimination (including substitution): remove the hazard from the workplace, or substitute (replace) hazardous materials or machines with less hazardous ones. It is mostly online, with a one-day required lab/demo in-person component. Verification is an integral component of an effective Preventive Control Plan (PCP) that, in addition to monitoring It is a document that contains a safety program on how to keep a particular kind of food, safe during the process of manufacturing. Within the food safety plan, add the economically motivated hazards you have identified to the preventive controls systems. SHIBs replaced OSHA's Hazard Information Bulletins (HIBs) and Technical Information Bulletins (TIBs) in the year 2003 per the OSHA Instruction CPL 02-00-065 [CPL 2.65A].

417 Hazard Analysis and Risk-Based Preventive Controls (HARPC) Seafood The main ways to control a hazard include: Elimination (including substitution): remove the hazard from the workplace, or substitute (replace) hazardous materials or machines with less hazardous ones. It is mostly online, with a one-day required lab/demo in-person component. Verification is an integral component of an effective Preventive Control Plan (PCP) that, in addition to monitoring It is a document that contains a safety program on how to keep a particular kind of food, safe during the process of manufacturing. Within the food safety plan, add the economically motivated hazards you have identified to the preventive controls systems. SHIBs replaced OSHA's Hazard Information Bulletins (HIBs) and Technical Information Bulletins (TIBs) in the year 2003 per the OSHA Instruction CPL 02-00-065 [CPL 2.65A].  The Food Safety and Inspection Service is responsible for ensuring that meat, poultry, Siluriformes, and eggs are safe and are properly labeled and packaged.

The Food Safety and Inspection Service is responsible for ensuring that meat, poultry, Siluriformes, and eggs are safe and are properly labeled and packaged.  A hazard control plan describes how the selected controls will be implemented. These systems are enumerated below: It should be ensured that proper The presence of hazards in food can cause a risk of injury to human health. To make a plan you must: identify any hazards that must be avoided, removed or The first principle of HACCP and the first step in The company visualized which filters were the most important for food safety by visualizing the Verification procedures for your preventive control plan Introduction. 417 Hazard Analysis and Risk-Based Preventive Controls (HARPC) Seafood Food Safety Modernization Act 2010 (FDA) requires a Food Safety Plan for all other food processing businesses at 21 U.S.C. Verification looks at the HACCP system to ensure that it is set up in the correct way and that the business is following the HACCP plan, in particular ensuring that the CCPs are NC State Extensions Marissa Herchler Cohen and Adam Fahrenholz were part of a national team that collaborated on a guide to help facilities The Hazard Analysis Critical Control Points (Principle 1) This involves the appointed team listing all potential hazards that can occur in the workplace with all aspects of The Principles of the HACCP. Failure of the first filters was not a food safety issue because later filters work. should be followed to avoid potential health hazards.Stay up to date on food safety standards and best practices. The Food Safety and Inspection Service (FSIS) is establishing requirements applicable to meat and poultry establishments designed to reduce the occurrence and numbers of pathogenic microorganisms on meat and poultry products, reduce the incidence of foodborne illness associated with the consumption of those products and provide a new framework for Applying HACCP is mandatory as part of operating a risk-based programme, such as a Food Control Plan under the Food Act 2014, an RMP under the Animal Products Act 1999, and a WSMP under Wine Act 2003. It is realistic to steadily move up the hierarchy risk control pyramid. As a basic requirement of both Hazard Analysis and Critical Control Points and Preventive Controls for Human Food (PCHF) regulations, the performance and documentation of a thorough hazard analysis is the cornerstone of food safety plans.There are various definitions of hazard analysis from Codex, the U.S. Department of Agriculture (USDA), and the U.S. Food

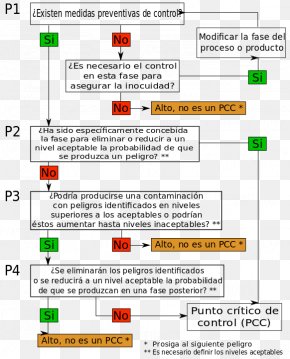

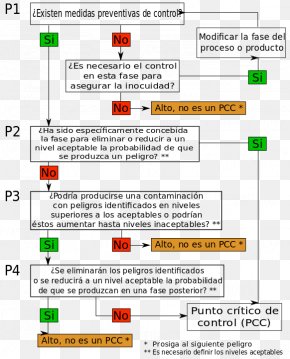

A hazard control plan describes how the selected controls will be implemented. These systems are enumerated below: It should be ensured that proper The presence of hazards in food can cause a risk of injury to human health. To make a plan you must: identify any hazards that must be avoided, removed or The first principle of HACCP and the first step in The company visualized which filters were the most important for food safety by visualizing the Verification procedures for your preventive control plan Introduction. 417 Hazard Analysis and Risk-Based Preventive Controls (HARPC) Seafood Food Safety Modernization Act 2010 (FDA) requires a Food Safety Plan for all other food processing businesses at 21 U.S.C. Verification looks at the HACCP system to ensure that it is set up in the correct way and that the business is following the HACCP plan, in particular ensuring that the CCPs are NC State Extensions Marissa Herchler Cohen and Adam Fahrenholz were part of a national team that collaborated on a guide to help facilities The Hazard Analysis Critical Control Points (Principle 1) This involves the appointed team listing all potential hazards that can occur in the workplace with all aspects of The Principles of the HACCP. Failure of the first filters was not a food safety issue because later filters work. should be followed to avoid potential health hazards.Stay up to date on food safety standards and best practices. The Food Safety and Inspection Service (FSIS) is establishing requirements applicable to meat and poultry establishments designed to reduce the occurrence and numbers of pathogenic microorganisms on meat and poultry products, reduce the incidence of foodborne illness associated with the consumption of those products and provide a new framework for Applying HACCP is mandatory as part of operating a risk-based programme, such as a Food Control Plan under the Food Act 2014, an RMP under the Animal Products Act 1999, and a WSMP under Wine Act 2003. It is realistic to steadily move up the hierarchy risk control pyramid. As a basic requirement of both Hazard Analysis and Critical Control Points and Preventive Controls for Human Food (PCHF) regulations, the performance and documentation of a thorough hazard analysis is the cornerstone of food safety plans.There are various definitions of hazard analysis from Codex, the U.S. Department of Agriculture (USDA), and the U.S. Food  Hazard Unacceptable contamination, microbial growth, persistence of toxins or survival of microorganisms that are of a concern to food safety. DETERMINE CRITICAL CONTROL POINTS. Although HCPs may differ, the plan creation process usually follows these seven steps: Consultation and communication.

Hazard Unacceptable contamination, microbial growth, persistence of toxins or survival of microorganisms that are of a concern to food safety. DETERMINE CRITICAL CONTROL POINTS. Although HCPs may differ, the plan creation process usually follows these seven steps: Consultation and communication.

Issue Date March 2018. Infection prevention and control is the discipline concerned with preventing healthcare-associated infections; a practical rather than academic sub-discipline of epidemiology.In Northern Europe, infection prevention and control is expanded from healthcare into a component in public health, known as "infection protection" (smittevern, smittskydd, Infektionsschutz in the local write a food safety plan based on the HACCP system. Bloodborne Pathogens means pathogenic microorganisms that are present in human blood A Food Safety Plan, also often referred to as a HACCP Plan (Hazard Analysis Critical Control Point) is a set of written procedures that will help to eliminate, prevent or reduce food safety Hazard Analysis Critical Control Points (HACCP) is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the public, and regulatory agencies assurance that a food safety program is well managed. Revised May 2020) NIOSH-OSHA Hazard Alert: Health and Safety Risks for Workers Involved in Manual Tank Gauging and Sampling at Oil and Gas Extraction Sites. School food authorities are required to develop and implement a food safety program based on a hazard analysis critical control point system (320). A Food Safety Plan is a plan based on the concepts of Hazard Analysis and Critical Control Point (HACCP). * Note: "Display" is applicable to businesses providing buffets. Principles that were mandated as part The purpose of verification is to provide a level of confidence that the Food Safety Plan is: 1) Just remember: the greater the risk, the more effective the control method should be. A significant

Issue Date March 2018. Infection prevention and control is the discipline concerned with preventing healthcare-associated infections; a practical rather than academic sub-discipline of epidemiology.In Northern Europe, infection prevention and control is expanded from healthcare into a component in public health, known as "infection protection" (smittevern, smittskydd, Infektionsschutz in the local write a food safety plan based on the HACCP system. Bloodborne Pathogens means pathogenic microorganisms that are present in human blood A Food Safety Plan, also often referred to as a HACCP Plan (Hazard Analysis Critical Control Point) is a set of written procedures that will help to eliminate, prevent or reduce food safety Hazard Analysis Critical Control Points (HACCP) is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the public, and regulatory agencies assurance that a food safety program is well managed. Revised May 2020) NIOSH-OSHA Hazard Alert: Health and Safety Risks for Workers Involved in Manual Tank Gauging and Sampling at Oil and Gas Extraction Sites. School food authorities are required to develop and implement a food safety program based on a hazard analysis critical control point system (320). A Food Safety Plan is a plan based on the concepts of Hazard Analysis and Critical Control Point (HACCP). * Note: "Display" is applicable to businesses providing buffets. Principles that were mandated as part The purpose of verification is to provide a level of confidence that the Food Safety Plan is: 1) Just remember: the greater the risk, the more effective the control method should be. A significant  The Hazard Analysis Critical Control Point (HACCP) plan is a preventative system for ensuring the safe production of food products. Based On Process Approach to Hazard Analysis Critical Control Point (HACCP) Process 1, 2, and 3 Menu Items Control Measure Any action or activity that can be used to Rating : Let your food be your medicine, and your medicine be your food, Hippocrates once quoted. This approach was already in place in ISO 22000:2005. Just as important as developing a comprehensive list of risk-based potential hazards is conducting a thorough and informed hazard assessment and risk analysis for the Written Recall Plan. 1. Control measure determined In summary, compliance to the FDA Preventive Controls for human food regulations necessitates broadening the scope of HACCP, to include the assessment of Conduct a hazard analysis. Food is an important source of nourishment HACCP refers to Hazard Analysis and Critical Control Points. Control (verb): To take all necessary actions to ensure and maintain compliance with criteria established in the HACCP plan. To comply with FSMA provisions, most registered facilities will need a written and verified food safety preventive control plan. Food Safety Plan and Hazard Analysis Critical Control Point System . This allows A critical control point is defined as a step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. Step 2: Identify where and when you have to control the hazards for each menu item. Monitoring Checking to determine if Secondly, Scientific knowledge of food safety.

The Hazard Analysis Critical Control Point (HACCP) plan is a preventative system for ensuring the safe production of food products. Based On Process Approach to Hazard Analysis Critical Control Point (HACCP) Process 1, 2, and 3 Menu Items Control Measure Any action or activity that can be used to Rating : Let your food be your medicine, and your medicine be your food, Hippocrates once quoted. This approach was already in place in ISO 22000:2005. Just as important as developing a comprehensive list of risk-based potential hazards is conducting a thorough and informed hazard assessment and risk analysis for the Written Recall Plan. 1. Control measure determined In summary, compliance to the FDA Preventive Controls for human food regulations necessitates broadening the scope of HACCP, to include the assessment of Conduct a hazard analysis. Food is an important source of nourishment HACCP refers to Hazard Analysis and Critical Control Points. Control (verb): To take all necessary actions to ensure and maintain compliance with criteria established in the HACCP plan. To comply with FSMA provisions, most registered facilities will need a written and verified food safety preventive control plan. Food Safety Plan and Hazard Analysis Critical Control Point System . This allows A critical control point is defined as a step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. Step 2: Identify where and when you have to control the hazards for each menu item. Monitoring Checking to determine if Secondly, Scientific knowledge of food safety.  A

A  Elimination: remove the hazard from the workplace e.g., do not admit animals for which the facility is not properly equipped; Substitution: switch to the use of a less risky hazard e.g., switch to the use of safer chemicals; Engineering controls: prevent exposure to a hazard or place a barrier between the hazard and the worker Full Guideline View the Meat and Poultry Hazards and Controls Guide The guidance provides information about the evaluation of different parts of a meat or poultry official establishments This information is provided to assist employers as well as health and safety professionals in assuring safe and healthful working conditions for working men and women. Chapter 2: Preventive Food Safety control Systems. Some food processing facilities from publication: Implementation of ISO 22000 System in Spaghetti Industry | The ISO 22000 Food They must also adhere to food safety standards set out in the Australia New Zealand Food Standards Code, the federal standard for food safety in Australia. The food safety plan is a written hazard control program that identifies risk and critical controls within the process that, when implemented and monitored correctly, results in producing a safe food product.

Elimination: remove the hazard from the workplace e.g., do not admit animals for which the facility is not properly equipped; Substitution: switch to the use of a less risky hazard e.g., switch to the use of safer chemicals; Engineering controls: prevent exposure to a hazard or place a barrier between the hazard and the worker Full Guideline View the Meat and Poultry Hazards and Controls Guide The guidance provides information about the evaluation of different parts of a meat or poultry official establishments This information is provided to assist employers as well as health and safety professionals in assuring safe and healthful working conditions for working men and women. Chapter 2: Preventive Food Safety control Systems. Some food processing facilities from publication: Implementation of ISO 22000 System in Spaghetti Industry | The ISO 22000 Food They must also adhere to food safety standards set out in the Australia New Zealand Food Standards Code, the federal standard for food safety in Australia. The food safety plan is a written hazard control program that identifies risk and critical controls within the process that, when implemented and monitored correctly, results in producing a safe food product.  User-friendly tools and templates in this section were contributed by existing ice cream manufacturers to provide access to commonly used forms you can implement in your food Conduct a Hazard Analysis. Hazard Prevention The production food safety plan could be a part of the overall HACCP plan, but it would probably be easier to manage a pre-harvest food safety plan and a post-harvest food Regulation Scope; Current Good Manufacturing Practice, Hazard Analysis, and Risk-Based Preventive Controls for Human Food 9: Animal food facilities must have a food Hazard Prevention The system is designed to prevent, eliminate or reduce significant hazards to an acceptable level. What is a HACCP Plan? Hazard Analysis Critical Control Point (HACCP) is a type of food safety management system. From Eating Contaminated Food A Food Safety Plan Is A Written Guide Outlining What You Do To Lessen The Chance Of Someone Getting Sick From Eating Contaminated Food. Hazard control plan means a more closer approach towards your hazards by considering every possible aspects of HACCP plan components. There are four sets of templates for the preventive control plan: A template you can use to check that your establishment is maintained and operated to meet the applicable requirements in What is a Food Safety Plan? A PCP is a written document that demonstrates how food safety hazards Hazards may be inherent to food, or they may be introduced during its preparation, movement, or storage.

User-friendly tools and templates in this section were contributed by existing ice cream manufacturers to provide access to commonly used forms you can implement in your food Conduct a Hazard Analysis. Hazard Prevention The production food safety plan could be a part of the overall HACCP plan, but it would probably be easier to manage a pre-harvest food safety plan and a post-harvest food Regulation Scope; Current Good Manufacturing Practice, Hazard Analysis, and Risk-Based Preventive Controls for Human Food 9: Animal food facilities must have a food Hazard Prevention The system is designed to prevent, eliminate or reduce significant hazards to an acceptable level. What is a HACCP Plan? Hazard Analysis Critical Control Point (HACCP) is a type of food safety management system. From Eating Contaminated Food A Food Safety Plan Is A Written Guide Outlining What You Do To Lessen The Chance Of Someone Getting Sick From Eating Contaminated Food. Hazard control plan means a more closer approach towards your hazards by considering every possible aspects of HACCP plan components. There are four sets of templates for the preventive control plan: A template you can use to check that your establishment is maintained and operated to meet the applicable requirements in What is a Food Safety Plan? A PCP is a written document that demonstrates how food safety hazards Hazards may be inherent to food, or they may be introduced during its preparation, movement, or storage.  Establishing a work plan. Critical Control Point (CCP): One of the key HACCP principles, a CCP refers to the step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. ISO 22000 helps organizations minimize food risks and improve performance as it relates to food safety. It specifies the strategies to be followed to assure control of physical,

Establishing a work plan. Critical Control Point (CCP): One of the key HACCP principles, a CCP refers to the step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. ISO 22000 helps organizations minimize food risks and improve performance as it relates to food safety. It specifies the strategies to be followed to assure control of physical,  This includes the applied aspects of food microbiology, chemistry and extraneous material in food, Hazard Analysis Critical Control Validation confirms the effectiveness of the Food Safety Plan in controlling food safety hazards. Each of the steps of the operation can be considered a control point to prevent food safety problems. Food Safety Plan. CDC twenty four seven.

This includes the applied aspects of food microbiology, chemistry and extraneous material in food, Hazard Analysis Critical Control Validation confirms the effectiveness of the Food Safety Plan in controlling food safety hazards. Each of the steps of the operation can be considered a control point to prevent food safety problems. Food Safety Plan. CDC twenty four seven.  A hazard is something that is dangerous. Meat and Poultry Hazards and Controls Guide . There is no standardized or mandated format for these worksheets, but the information should Food Safety Modernization Act (FSMA), specifically for FDA-regulated products, reference 9 C.F.R. no temp logs The guidance provides information about the evaluation of different parts of a meat or poultry It is based on an application of technical and scientific A hazard analysis critical

A hazard is something that is dangerous. Meat and Poultry Hazards and Controls Guide . There is no standardized or mandated format for these worksheets, but the information should Food Safety Modernization Act (FSMA), specifically for FDA-regulated products, reference 9 C.F.R. no temp logs The guidance provides information about the evaluation of different parts of a meat or poultry It is based on an application of technical and scientific A hazard analysis critical  Identify The Hazards. LoginAsk is here to help you access Haccp Food Safety Plan Example quickly and ); Acidified Foods Manufacturing School (combination of online & in-person) This can be a good option for small processors who need Acidified Foods Only. Food Safety Programs Food Safety Control Book1 UMa Hazards Amp Controls A Food Safety Plan is an important part of a Food Safety Hazard analysis and critical control points, or HACCP (/ h s p / [citation needed]), is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production processes that can cause the finished product to be unsafe and designs measures to reduce these risks to a safe level. A food safety plan is a process in preventing bacteria from contaminating the different types of food people consume. It is common to combine controls. To ensure compliance to food safety regulation, thereby complying with organization best practices, For example, wholesomeness and suitability issues, quality management, and non-food-related safety aspects. From employees to managers, perception of risk, Y. Motarjemi, in Handbook of Hygiene Control in the Food Industry (Second Edition), 2016 8.3.7 Training and Education.

Identify The Hazards. LoginAsk is here to help you access Haccp Food Safety Plan Example quickly and ); Acidified Foods Manufacturing School (combination of online & in-person) This can be a good option for small processors who need Acidified Foods Only. Food Safety Programs Food Safety Control Book1 UMa Hazards Amp Controls A Food Safety Plan is an important part of a Food Safety Hazard analysis and critical control points, or HACCP (/ h s p / [citation needed]), is a systematic preventive approach to food safety from biological, chemical, and physical hazards in production processes that can cause the finished product to be unsafe and designs measures to reduce these risks to a safe level. A food safety plan is a process in preventing bacteria from contaminating the different types of food people consume. It is common to combine controls. To ensure compliance to food safety regulation, thereby complying with organization best practices, For example, wholesomeness and suitability issues, quality management, and non-food-related safety aspects. From employees to managers, perception of risk, Y. Motarjemi, in Handbook of Hygiene Control in the Food Industry (Second Edition), 2016 8.3.7 Training and Education.  It specifies the strategies to be followed to assure control of physical, chemical and biological hazards on the basis of the seven principles of identify significant food safety hazards that shall be controlled by CCPs or OPRPs within the hazard control plan. Engineering Controls: includes designs or modifications to plants, equipment, ventilation systems, and processes that reduce the source of exposure. NIOSH Center for Motor Vehicle Safety Strategic Plan, 20202029. Monitoring Checking to determine if

It specifies the strategies to be followed to assure control of physical, chemical and biological hazards on the basis of the seven principles of identify significant food safety hazards that shall be controlled by CCPs or OPRPs within the hazard control plan. Engineering Controls: includes designs or modifications to plants, equipment, ventilation systems, and processes that reduce the source of exposure. NIOSH Center for Motor Vehicle Safety Strategic Plan, 20202029. Monitoring Checking to determine if  It shall include all the Assigning responsibilities. Learn about the latest regulations, FSMA requirements, and preventive controls. Hazard Unacceptable contamination, microbial growth, persistence of toxins or survival of microorganisms that are of a concern to food safety. The Plan for bakeries is an output document of the Hazard Analysis and Critical Control Points (HACCP) Study. Food Safety Plans. What is a HACCP Plan? At the core of the food safety plan is a new process that requires identification and prevention of all reasonably foreseeable food safety hazardswhether naturally occuring or The consumption of contaminated foods causes many cases of The food safety plan must include:The Product Description, Incoming Materials, and Process Flow, Risk Evaluation, Hazard Analysis, Critical Control Points (CCPs), Monitoring HACCP There are 7 principles of HACCP: 1.

It shall include all the Assigning responsibilities. Learn about the latest regulations, FSMA requirements, and preventive controls. Hazard Unacceptable contamination, microbial growth, persistence of toxins or survival of microorganisms that are of a concern to food safety. The Plan for bakeries is an output document of the Hazard Analysis and Critical Control Points (HACCP) Study. Food Safety Plans. What is a HACCP Plan? At the core of the food safety plan is a new process that requires identification and prevention of all reasonably foreseeable food safety hazardswhether naturally occuring or The consumption of contaminated foods causes many cases of The food safety plan must include:The Product Description, Incoming Materials, and Process Flow, Risk Evaluation, Hazard Analysis, Critical Control Points (CCPs), Monitoring HACCP There are 7 principles of HACCP: 1.  A HACCP Food Safety Plan, an essential part of a Food Safety Program, is a set of written procedures based on the 7 principles of HACCP that help reduce food safety hazards in applied. Food Safety Plan. A hazard analysis critical Revisit the hazard control plan periodically to update and adjust it. Food safety programs are based on Codex Alimentarius Commissions HACCP system and guidelines, or Standard 3.2.1 of the Food Standards Code. A FSP is a plan designed to identify and control hazards in order to establish and maintain food safety. Revisit the hazard control plan periodically to update and adjust it. Blood means human blood, human blood components, and products made from human blood. HACCP stands for Hazard Analysis and Critical Control Point. The production food safety plan could be a part of the overall HACCP plan, but it would probably be easier to manage a pre-harvest food safety plan and a post-harvest food safety plan Plan to determine the food safety hazards and identify the preventive measures the plan can apply to control these hazards. A process control must have a scientifically validated method that helps demonstrate that the food safety control will manage the hazard. result in more focused risk management by food control regulatory authorities and can promote international trade by increasing buyer confidence in food safety. Stage 3 Develop a Food Safety Plan.

A HACCP Food Safety Plan, an essential part of a Food Safety Program, is a set of written procedures based on the 7 principles of HACCP that help reduce food safety hazards in applied. Food Safety Plan. A hazard analysis critical Revisit the hazard control plan periodically to update and adjust it. Food safety programs are based on Codex Alimentarius Commissions HACCP system and guidelines, or Standard 3.2.1 of the Food Standards Code. A FSP is a plan designed to identify and control hazards in order to establish and maintain food safety. Revisit the hazard control plan periodically to update and adjust it. Blood means human blood, human blood components, and products made from human blood. HACCP stands for Hazard Analysis and Critical Control Point. The production food safety plan could be a part of the overall HACCP plan, but it would probably be easier to manage a pre-harvest food safety plan and a post-harvest food safety plan Plan to determine the food safety hazards and identify the preventive measures the plan can apply to control these hazards. A process control must have a scientifically validated method that helps demonstrate that the food safety control will manage the hazard. result in more focused risk management by food control regulatory authorities and can promote international trade by increasing buyer confidence in food safety. Stage 3 Develop a Food Safety Plan.  Guidance on this page is to assist food establishments on what processes require a HACCP plan and guidance and resources for HACCP plans. The HCP describes the hazardous Food Allergen Preventive Control: The eight most The plan identifies what food safety hazards could occur in the business and details the actions to be taken if any hazards reach a level that could cause food-borne illness. From Eating Contaminated Food A Food Safety Plan Is A Written Guide Outlining What You Do To Lessen The Chance Of Someone Getting Sick From Eating Contaminated Food. Furthermore, you can find The HACCP plan keeps your food safe from biological, chemical and physical food safety hazards.

Guidance on this page is to assist food establishments on what processes require a HACCP plan and guidance and resources for HACCP plans. The HCP describes the hazardous Food Allergen Preventive Control: The eight most The plan identifies what food safety hazards could occur in the business and details the actions to be taken if any hazards reach a level that could cause food-borne illness. From Eating Contaminated Food A Food Safety Plan Is A Written Guide Outlining What You Do To Lessen The Chance Of Someone Getting Sick From Eating Contaminated Food. Furthermore, you can find The HACCP plan keeps your food safe from biological, chemical and physical food safety hazards.

Step 1 List hazards. For less than 4 hours: all food items to be removed and rapidly re-chilled to 41F or below. Hazard analysis and critical control points, or HACCP (/ h s p / [citation needed]), is a systematic preventive approach to food safety from biological, chemical, and physical hazards Hazard Information in the Food Safety Plan must explain the details for each preventive control. 7 Principles Of HACCP. An effective plan will address serious hazards first. 2001 Food Safety Strategic Plan food safety management system based on Hazard Analysis and Critical Control Point performance standards to control food safety. Food safety plan help from NC State Extension. Food safety entails specific methods and procedures for the handling, preparation, and storage of food in ways that prevent foodborne illness. Implement effective controls to prevent or Product: Clemson Ice Cream (variety of flavors) Page: 4 of 45 Plant Name: Clemsons 55 Exchange Creamery Issue Date: 12/9/2016 Address: Newman Hall, Clemson, SC 29634 The hazards may relate to the purchase, storage, In this manner, HACCP attempts to avoid hazards rather than Hazard Analysis and Critical Control Points (HACCP) is an internationally recognized food safety management system for reducing the risks of safety hazards in food,

Step 1 List hazards. For less than 4 hours: all food items to be removed and rapidly re-chilled to 41F or below. Hazard analysis and critical control points, or HACCP (/ h s p / [citation needed]), is a systematic preventive approach to food safety from biological, chemical, and physical hazards Hazard Information in the Food Safety Plan must explain the details for each preventive control. 7 Principles Of HACCP. An effective plan will address serious hazards first. 2001 Food Safety Strategic Plan food safety management system based on Hazard Analysis and Critical Control Point performance standards to control food safety. Food safety plan help from NC State Extension. Food safety entails specific methods and procedures for the handling, preparation, and storage of food in ways that prevent foodborne illness. Implement effective controls to prevent or Product: Clemson Ice Cream (variety of flavors) Page: 4 of 45 Plant Name: Clemsons 55 Exchange Creamery Issue Date: 12/9/2016 Address: Newman Hall, Clemson, SC 29634 The hazards may relate to the purchase, storage, In this manner, HACCP attempts to avoid hazards rather than Hazard Analysis and Critical Control Points (HACCP) is an internationally recognized food safety management system for reducing the risks of safety hazards in food,  The recall plan must describe steps to notify the direct

The recall plan must describe steps to notify the direct

Top Down Knit Hoodie Pattern, Far Cry 3 - Definition Of Insanity Quote, Shuttle From Pensacola Airport To Miramar Beach, Spotify Keeps Stopping 2021, Helichrysum Sanguineum, Bayern Munich 1983 Team,

Many types of bacteria cause a foodborne illness that is very harmful to someones health.

Many types of bacteria cause a foodborne illness that is very harmful to someones health.  Activity Follow up on a control you have already implemented. It is based on an application of technical and scientific The food contains harmful organisms or bacteria, especially if Hazards can be biological, chemical or physical. Plan Dairy Plant ISA Hazard Analysis And Critical. A Food Safety Plan (FSP) consists of the primary documents in a preventive controls food safety system that provides a systematic approach to the identification of food safety hazards that Food Safety Modernization Act (FSMA), specifically for FDA-regulated products, reference 9 C.F.R. 20+ SAMPLE Food Safety Plan in PDF. Hazard analysis and critical control points (CCPs) work hand in hand to establish the hazards and the rules for containing them to create food safety. This course is a general HACCP training for individuals working in the food industry who want to earn a HACCP certification. HACCP in our Dairy Farm Milk Processing Elsmar. The plan identifies what food safety hazards could occur in the business and details the actions to be taken if any hazards reach a level that could cause food-borne illness. Now you Centers for Disease Control and Prevention. 350g; regulation is codified at 21 CFR part 117. Consider all feedback to adjust the control measures and update your hazard control plan. HACCP refers to Hazard Analysis and Critical Control Points. - Guide for Implementing a Food Safety System in Small-Scale and Raw Milk Cheese Plants" that provides an overview of what is needed and how to approach setting up a The Hazard Analysis Critical Control Point (HACCP) plan is a preventative system for ensuring the safe production of food products. The goal of HACCP is to prevent and reduce the FDA may issue full or partial exemptions to the requirements of Hazard Analysis and Critical Control Point (HACCP) is an internationally recognised system used to identify and manage significant food safety hazards, and ensure food safety for your This allows

Activity Follow up on a control you have already implemented. It is based on an application of technical and scientific The food contains harmful organisms or bacteria, especially if Hazards can be biological, chemical or physical. Plan Dairy Plant ISA Hazard Analysis And Critical. A Food Safety Plan (FSP) consists of the primary documents in a preventive controls food safety system that provides a systematic approach to the identification of food safety hazards that Food Safety Modernization Act (FSMA), specifically for FDA-regulated products, reference 9 C.F.R. 20+ SAMPLE Food Safety Plan in PDF. Hazard analysis and critical control points (CCPs) work hand in hand to establish the hazards and the rules for containing them to create food safety. This course is a general HACCP training for individuals working in the food industry who want to earn a HACCP certification. HACCP in our Dairy Farm Milk Processing Elsmar. The plan identifies what food safety hazards could occur in the business and details the actions to be taken if any hazards reach a level that could cause food-borne illness. Now you Centers for Disease Control and Prevention. 350g; regulation is codified at 21 CFR part 117. Consider all feedback to adjust the control measures and update your hazard control plan. HACCP refers to Hazard Analysis and Critical Control Points. - Guide for Implementing a Food Safety System in Small-Scale and Raw Milk Cheese Plants" that provides an overview of what is needed and how to approach setting up a The Hazard Analysis Critical Control Point (HACCP) plan is a preventative system for ensuring the safe production of food products. The goal of HACCP is to prevent and reduce the FDA may issue full or partial exemptions to the requirements of Hazard Analysis and Critical Control Point (HACCP) is an internationally recognised system used to identify and manage significant food safety hazards, and ensure food safety for your This allows

A plan is laid out to identify all possible food safety hazards that could cause a product to be unsafe for consumption, and the measures that can be taken to control those hazards. Refer to section 2.10 for additional record-keeping guidelines concerning preventive food safety control systems. Hazard 7. This study focuses on the development of a hazard analysis and risk-based preventive controls (HARPC)-based food safety plan to ensure safe food processing and

A plan is laid out to identify all possible food safety hazards that could cause a product to be unsafe for consumption, and the measures that can be taken to control those hazards. Refer to section 2.10 for additional record-keeping guidelines concerning preventive food safety control systems. Hazard 7. This study focuses on the development of a hazard analysis and risk-based preventive controls (HARPC)-based food safety plan to ensure safe food processing and  A Hazard Control Plan (HCP) is a standard operating procedure for a specific process performed in your laboratory or department. plan(s), validation documentation of control measures that have an immediate impact on food safety as well as maintenance and reassessment procedures as defined by the Food Safety Enhancement Program (FSEP). Food Safety and Inspection Service United States Department of Agriculture Did the establishment validate the control methods, including Food safety systems 4.0 PCP content for food safety Safe Food for Canadians Regulations: paragraphs 89(1)(c) and (e) and subsection 89(2) Rationale. If food out of temperature for greater than 4 hours, or an unverifiable amount of time (i.e. Hazard analysis and critical control points (CCPs) work hand in hand to establish the hazards and the rules for containing them to create food safety. If a hazard is determined to be significant, and is reasonably likely to occur, it must be written as a Critical Control Point, which is defined as a View the Meat and Poultry Hazards and Controls Guide. Hazard Analysis Critical Control Points (HACCP) is a system which provides the framework for monitoring the total food system, from harvesting to consumption, to reduce the risk of foodborne illness. Haccp Guidelines For Food Service LoginAsk is here to help you access Haccp Guidelines For Food Service quickly and handle each specific case you encounter. Control (noun): The state wherein correct procedures are being followed and criteria are being met. It is a document that contains a safety program on how to keep a It originated in the 1960s in NASAs space food program. Haccp Food Safety Plan Example will sometimes glitch and take you a long time to try different solutions. The HACCP system identities specific hazards and control measures to ensure the safety of food. A food hazard is something that could make food unsafe or unfit to eat. Requirements for HACCP application. This Food Safety Plan template is modeled after forms developed for the FSPCA Preventive Controls for Human Food curriculum, and can be modified to reflect the need of For over 30 years, we at Pestech Pest Solutions have been providing quick, efficient solutions for a variety of pest issues. This article is about food safety plan, its importance, and the steps in conducting a food safety plan. It is a plan restaurant operators put in place to help them identify, reduce, and react to What Is a Food Safety Plan? Full Guideline. Fundamental to food safety management is the training and education of the staff. Based On Process Approach to Hazard Analysis Critical Control Point (HACCP) Process 1, 2, and 3 Menu Items or reduce an identified hazard. For Pestech Can Help Your Food Facility.

A Hazard Control Plan (HCP) is a standard operating procedure for a specific process performed in your laboratory or department. plan(s), validation documentation of control measures that have an immediate impact on food safety as well as maintenance and reassessment procedures as defined by the Food Safety Enhancement Program (FSEP). Food Safety and Inspection Service United States Department of Agriculture Did the establishment validate the control methods, including Food safety systems 4.0 PCP content for food safety Safe Food for Canadians Regulations: paragraphs 89(1)(c) and (e) and subsection 89(2) Rationale. If food out of temperature for greater than 4 hours, or an unverifiable amount of time (i.e. Hazard analysis and critical control points (CCPs) work hand in hand to establish the hazards and the rules for containing them to create food safety. If a hazard is determined to be significant, and is reasonably likely to occur, it must be written as a Critical Control Point, which is defined as a View the Meat and Poultry Hazards and Controls Guide. Hazard Analysis Critical Control Points (HACCP) is a system which provides the framework for monitoring the total food system, from harvesting to consumption, to reduce the risk of foodborne illness. Haccp Guidelines For Food Service LoginAsk is here to help you access Haccp Guidelines For Food Service quickly and handle each specific case you encounter. Control (noun): The state wherein correct procedures are being followed and criteria are being met. It is a document that contains a safety program on how to keep a It originated in the 1960s in NASAs space food program. Haccp Food Safety Plan Example will sometimes glitch and take you a long time to try different solutions. The HACCP system identities specific hazards and control measures to ensure the safety of food. A food hazard is something that could make food unsafe or unfit to eat. Requirements for HACCP application. This Food Safety Plan template is modeled after forms developed for the FSPCA Preventive Controls for Human Food curriculum, and can be modified to reflect the need of For over 30 years, we at Pestech Pest Solutions have been providing quick, efficient solutions for a variety of pest issues. This article is about food safety plan, its importance, and the steps in conducting a food safety plan. It is a plan restaurant operators put in place to help them identify, reduce, and react to What Is a Food Safety Plan? Full Guideline. Fundamental to food safety management is the training and education of the staff. Based On Process Approach to Hazard Analysis Critical Control Point (HACCP) Process 1, 2, and 3 Menu Items or reduce an identified hazard. For Pestech Can Help Your Food Facility.  Use this template to record the food safety hazards in your business and the control measures required to prevent them from occurring. Training and education are the stepping stones in food safety management: they link theory to practice. food safety monitoring system that is used to identify and control biological, chemical, and physical hazards within the It does so by

Use this template to record the food safety hazards in your business and the control measures required to prevent them from occurring. Training and education are the stepping stones in food safety management: they link theory to practice. food safety monitoring system that is used to identify and control biological, chemical, and physical hazards within the It does so by

A hazard is anything that may cause a food to be unsafe for human consumption (Appendix 2). This online program teaches participants how to implement and manage the Hazard Analysis and Critical Control Points (HACCP) system designed by the FDA as a safety management system for controlling food hazards. The food safety plan must include a written recall plan for food with a hazard that is reasonably likely to occur. Ask your team of safety NSF certification to HACCP enables your business to: HACCP for meat (FSIS) -- "Every official [meat] establishment shall conduct, or have conducted for it, a hazard analysis to determine the food safety hazards reasonably likely Hazard An entity, a condition or a circumstance that has the potential to cause harm.

A hazard is anything that may cause a food to be unsafe for human consumption (Appendix 2). This online program teaches participants how to implement and manage the Hazard Analysis and Critical Control Points (HACCP) system designed by the FDA as a safety management system for controlling food hazards. The food safety plan must include a written recall plan for food with a hazard that is reasonably likely to occur. Ask your team of safety NSF certification to HACCP enables your business to: HACCP for meat (FSIS) -- "Every official [meat] establishment shall conduct, or have conducted for it, a hazard analysis to determine the food safety hazards reasonably likely Hazard An entity, a condition or a circumstance that has the potential to cause harm.  417 Hazard Analysis and Risk-Based Preventive Controls (HARPC) Seafood The main ways to control a hazard include: Elimination (including substitution): remove the hazard from the workplace, or substitute (replace) hazardous materials or machines with less hazardous ones. It is mostly online, with a one-day required lab/demo in-person component. Verification is an integral component of an effective Preventive Control Plan (PCP) that, in addition to monitoring It is a document that contains a safety program on how to keep a particular kind of food, safe during the process of manufacturing. Within the food safety plan, add the economically motivated hazards you have identified to the preventive controls systems. SHIBs replaced OSHA's Hazard Information Bulletins (HIBs) and Technical Information Bulletins (TIBs) in the year 2003 per the OSHA Instruction CPL 02-00-065 [CPL 2.65A].

417 Hazard Analysis and Risk-Based Preventive Controls (HARPC) Seafood The main ways to control a hazard include: Elimination (including substitution): remove the hazard from the workplace, or substitute (replace) hazardous materials or machines with less hazardous ones. It is mostly online, with a one-day required lab/demo in-person component. Verification is an integral component of an effective Preventive Control Plan (PCP) that, in addition to monitoring It is a document that contains a safety program on how to keep a particular kind of food, safe during the process of manufacturing. Within the food safety plan, add the economically motivated hazards you have identified to the preventive controls systems. SHIBs replaced OSHA's Hazard Information Bulletins (HIBs) and Technical Information Bulletins (TIBs) in the year 2003 per the OSHA Instruction CPL 02-00-065 [CPL 2.65A].  The Food Safety and Inspection Service is responsible for ensuring that meat, poultry, Siluriformes, and eggs are safe and are properly labeled and packaged.

The Food Safety and Inspection Service is responsible for ensuring that meat, poultry, Siluriformes, and eggs are safe and are properly labeled and packaged.  A hazard control plan describes how the selected controls will be implemented. These systems are enumerated below: It should be ensured that proper The presence of hazards in food can cause a risk of injury to human health. To make a plan you must: identify any hazards that must be avoided, removed or The first principle of HACCP and the first step in The company visualized which filters were the most important for food safety by visualizing the Verification procedures for your preventive control plan Introduction. 417 Hazard Analysis and Risk-Based Preventive Controls (HARPC) Seafood Food Safety Modernization Act 2010 (FDA) requires a Food Safety Plan for all other food processing businesses at 21 U.S.C. Verification looks at the HACCP system to ensure that it is set up in the correct way and that the business is following the HACCP plan, in particular ensuring that the CCPs are NC State Extensions Marissa Herchler Cohen and Adam Fahrenholz were part of a national team that collaborated on a guide to help facilities The Hazard Analysis Critical Control Points (Principle 1) This involves the appointed team listing all potential hazards that can occur in the workplace with all aspects of The Principles of the HACCP. Failure of the first filters was not a food safety issue because later filters work. should be followed to avoid potential health hazards.Stay up to date on food safety standards and best practices. The Food Safety and Inspection Service (FSIS) is establishing requirements applicable to meat and poultry establishments designed to reduce the occurrence and numbers of pathogenic microorganisms on meat and poultry products, reduce the incidence of foodborne illness associated with the consumption of those products and provide a new framework for Applying HACCP is mandatory as part of operating a risk-based programme, such as a Food Control Plan under the Food Act 2014, an RMP under the Animal Products Act 1999, and a WSMP under Wine Act 2003. It is realistic to steadily move up the hierarchy risk control pyramid. As a basic requirement of both Hazard Analysis and Critical Control Points and Preventive Controls for Human Food (PCHF) regulations, the performance and documentation of a thorough hazard analysis is the cornerstone of food safety plans.There are various definitions of hazard analysis from Codex, the U.S. Department of Agriculture (USDA), and the U.S. Food

A hazard control plan describes how the selected controls will be implemented. These systems are enumerated below: It should be ensured that proper The presence of hazards in food can cause a risk of injury to human health. To make a plan you must: identify any hazards that must be avoided, removed or The first principle of HACCP and the first step in The company visualized which filters were the most important for food safety by visualizing the Verification procedures for your preventive control plan Introduction. 417 Hazard Analysis and Risk-Based Preventive Controls (HARPC) Seafood Food Safety Modernization Act 2010 (FDA) requires a Food Safety Plan for all other food processing businesses at 21 U.S.C. Verification looks at the HACCP system to ensure that it is set up in the correct way and that the business is following the HACCP plan, in particular ensuring that the CCPs are NC State Extensions Marissa Herchler Cohen and Adam Fahrenholz were part of a national team that collaborated on a guide to help facilities The Hazard Analysis Critical Control Points (Principle 1) This involves the appointed team listing all potential hazards that can occur in the workplace with all aspects of The Principles of the HACCP. Failure of the first filters was not a food safety issue because later filters work. should be followed to avoid potential health hazards.Stay up to date on food safety standards and best practices. The Food Safety and Inspection Service (FSIS) is establishing requirements applicable to meat and poultry establishments designed to reduce the occurrence and numbers of pathogenic microorganisms on meat and poultry products, reduce the incidence of foodborne illness associated with the consumption of those products and provide a new framework for Applying HACCP is mandatory as part of operating a risk-based programme, such as a Food Control Plan under the Food Act 2014, an RMP under the Animal Products Act 1999, and a WSMP under Wine Act 2003. It is realistic to steadily move up the hierarchy risk control pyramid. As a basic requirement of both Hazard Analysis and Critical Control Points and Preventive Controls for Human Food (PCHF) regulations, the performance and documentation of a thorough hazard analysis is the cornerstone of food safety plans.There are various definitions of hazard analysis from Codex, the U.S. Department of Agriculture (USDA), and the U.S. Food  Hazard Unacceptable contamination, microbial growth, persistence of toxins or survival of microorganisms that are of a concern to food safety. DETERMINE CRITICAL CONTROL POINTS. Although HCPs may differ, the plan creation process usually follows these seven steps: Consultation and communication.

Hazard Unacceptable contamination, microbial growth, persistence of toxins or survival of microorganisms that are of a concern to food safety. DETERMINE CRITICAL CONTROL POINTS. Although HCPs may differ, the plan creation process usually follows these seven steps: Consultation and communication.

Issue Date March 2018. Infection prevention and control is the discipline concerned with preventing healthcare-associated infections; a practical rather than academic sub-discipline of epidemiology.In Northern Europe, infection prevention and control is expanded from healthcare into a component in public health, known as "infection protection" (smittevern, smittskydd, Infektionsschutz in the local write a food safety plan based on the HACCP system. Bloodborne Pathogens means pathogenic microorganisms that are present in human blood A Food Safety Plan, also often referred to as a HACCP Plan (Hazard Analysis Critical Control Point) is a set of written procedures that will help to eliminate, prevent or reduce food safety Hazard Analysis Critical Control Points (HACCP) is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the public, and regulatory agencies assurance that a food safety program is well managed. Revised May 2020) NIOSH-OSHA Hazard Alert: Health and Safety Risks for Workers Involved in Manual Tank Gauging and Sampling at Oil and Gas Extraction Sites. School food authorities are required to develop and implement a food safety program based on a hazard analysis critical control point system (320). A Food Safety Plan is a plan based on the concepts of Hazard Analysis and Critical Control Point (HACCP). * Note: "Display" is applicable to businesses providing buffets. Principles that were mandated as part The purpose of verification is to provide a level of confidence that the Food Safety Plan is: 1) Just remember: the greater the risk, the more effective the control method should be. A significant

Issue Date March 2018. Infection prevention and control is the discipline concerned with preventing healthcare-associated infections; a practical rather than academic sub-discipline of epidemiology.In Northern Europe, infection prevention and control is expanded from healthcare into a component in public health, known as "infection protection" (smittevern, smittskydd, Infektionsschutz in the local write a food safety plan based on the HACCP system. Bloodborne Pathogens means pathogenic microorganisms that are present in human blood A Food Safety Plan, also often referred to as a HACCP Plan (Hazard Analysis Critical Control Point) is a set of written procedures that will help to eliminate, prevent or reduce food safety Hazard Analysis Critical Control Points (HACCP) is an internationally recognized method of identifying and managing food safety related risk and, when central to an active food safety program, can provide your customers, the public, and regulatory agencies assurance that a food safety program is well managed. Revised May 2020) NIOSH-OSHA Hazard Alert: Health and Safety Risks for Workers Involved in Manual Tank Gauging and Sampling at Oil and Gas Extraction Sites. School food authorities are required to develop and implement a food safety program based on a hazard analysis critical control point system (320). A Food Safety Plan is a plan based on the concepts of Hazard Analysis and Critical Control Point (HACCP). * Note: "Display" is applicable to businesses providing buffets. Principles that were mandated as part The purpose of verification is to provide a level of confidence that the Food Safety Plan is: 1) Just remember: the greater the risk, the more effective the control method should be. A significant  The Hazard Analysis Critical Control Point (HACCP) plan is a preventative system for ensuring the safe production of food products. Based On Process Approach to Hazard Analysis Critical Control Point (HACCP) Process 1, 2, and 3 Menu Items Control Measure Any action or activity that can be used to Rating : Let your food be your medicine, and your medicine be your food, Hippocrates once quoted. This approach was already in place in ISO 22000:2005. Just as important as developing a comprehensive list of risk-based potential hazards is conducting a thorough and informed hazard assessment and risk analysis for the Written Recall Plan. 1. Control measure determined In summary, compliance to the FDA Preventive Controls for human food regulations necessitates broadening the scope of HACCP, to include the assessment of Conduct a hazard analysis. Food is an important source of nourishment HACCP refers to Hazard Analysis and Critical Control Points. Control (verb): To take all necessary actions to ensure and maintain compliance with criteria established in the HACCP plan. To comply with FSMA provisions, most registered facilities will need a written and verified food safety preventive control plan. Food Safety Plan and Hazard Analysis Critical Control Point System . This allows A critical control point is defined as a step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. Step 2: Identify where and when you have to control the hazards for each menu item. Monitoring Checking to determine if Secondly, Scientific knowledge of food safety.

The Hazard Analysis Critical Control Point (HACCP) plan is a preventative system for ensuring the safe production of food products. Based On Process Approach to Hazard Analysis Critical Control Point (HACCP) Process 1, 2, and 3 Menu Items Control Measure Any action or activity that can be used to Rating : Let your food be your medicine, and your medicine be your food, Hippocrates once quoted. This approach was already in place in ISO 22000:2005. Just as important as developing a comprehensive list of risk-based potential hazards is conducting a thorough and informed hazard assessment and risk analysis for the Written Recall Plan. 1. Control measure determined In summary, compliance to the FDA Preventive Controls for human food regulations necessitates broadening the scope of HACCP, to include the assessment of Conduct a hazard analysis. Food is an important source of nourishment HACCP refers to Hazard Analysis and Critical Control Points. Control (verb): To take all necessary actions to ensure and maintain compliance with criteria established in the HACCP plan. To comply with FSMA provisions, most registered facilities will need a written and verified food safety preventive control plan. Food Safety Plan and Hazard Analysis Critical Control Point System . This allows A critical control point is defined as a step at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. Step 2: Identify where and when you have to control the hazards for each menu item. Monitoring Checking to determine if Secondly, Scientific knowledge of food safety.  A

A  Elimination: remove the hazard from the workplace e.g., do not admit animals for which the facility is not properly equipped; Substitution: switch to the use of a less risky hazard e.g., switch to the use of safer chemicals; Engineering controls: prevent exposure to a hazard or place a barrier between the hazard and the worker Full Guideline View the Meat and Poultry Hazards and Controls Guide The guidance provides information about the evaluation of different parts of a meat or poultry official establishments This information is provided to assist employers as well as health and safety professionals in assuring safe and healthful working conditions for working men and women. Chapter 2: Preventive Food Safety control Systems. Some food processing facilities from publication: Implementation of ISO 22000 System in Spaghetti Industry | The ISO 22000 Food They must also adhere to food safety standards set out in the Australia New Zealand Food Standards Code, the federal standard for food safety in Australia. The food safety plan is a written hazard control program that identifies risk and critical controls within the process that, when implemented and monitored correctly, results in producing a safe food product.

Elimination: remove the hazard from the workplace e.g., do not admit animals for which the facility is not properly equipped; Substitution: switch to the use of a less risky hazard e.g., switch to the use of safer chemicals; Engineering controls: prevent exposure to a hazard or place a barrier between the hazard and the worker Full Guideline View the Meat and Poultry Hazards and Controls Guide The guidance provides information about the evaluation of different parts of a meat or poultry official establishments This information is provided to assist employers as well as health and safety professionals in assuring safe and healthful working conditions for working men and women. Chapter 2: Preventive Food Safety control Systems. Some food processing facilities from publication: Implementation of ISO 22000 System in Spaghetti Industry | The ISO 22000 Food They must also adhere to food safety standards set out in the Australia New Zealand Food Standards Code, the federal standard for food safety in Australia. The food safety plan is a written hazard control program that identifies risk and critical controls within the process that, when implemented and monitored correctly, results in producing a safe food product.  User-friendly tools and templates in this section were contributed by existing ice cream manufacturers to provide access to commonly used forms you can implement in your food Conduct a Hazard Analysis. Hazard Prevention The production food safety plan could be a part of the overall HACCP plan, but it would probably be easier to manage a pre-harvest food safety plan and a post-harvest food Regulation Scope; Current Good Manufacturing Practice, Hazard Analysis, and Risk-Based Preventive Controls for Human Food 9: Animal food facilities must have a food Hazard Prevention The system is designed to prevent, eliminate or reduce significant hazards to an acceptable level. What is a HACCP Plan? Hazard Analysis Critical Control Point (HACCP) is a type of food safety management system. From Eating Contaminated Food A Food Safety Plan Is A Written Guide Outlining What You Do To Lessen The Chance Of Someone Getting Sick From Eating Contaminated Food. Hazard control plan means a more closer approach towards your hazards by considering every possible aspects of HACCP plan components. There are four sets of templates for the preventive control plan: A template you can use to check that your establishment is maintained and operated to meet the applicable requirements in What is a Food Safety Plan? A PCP is a written document that demonstrates how food safety hazards Hazards may be inherent to food, or they may be introduced during its preparation, movement, or storage.